Overview of Oil Sludge Disposal Technology Products

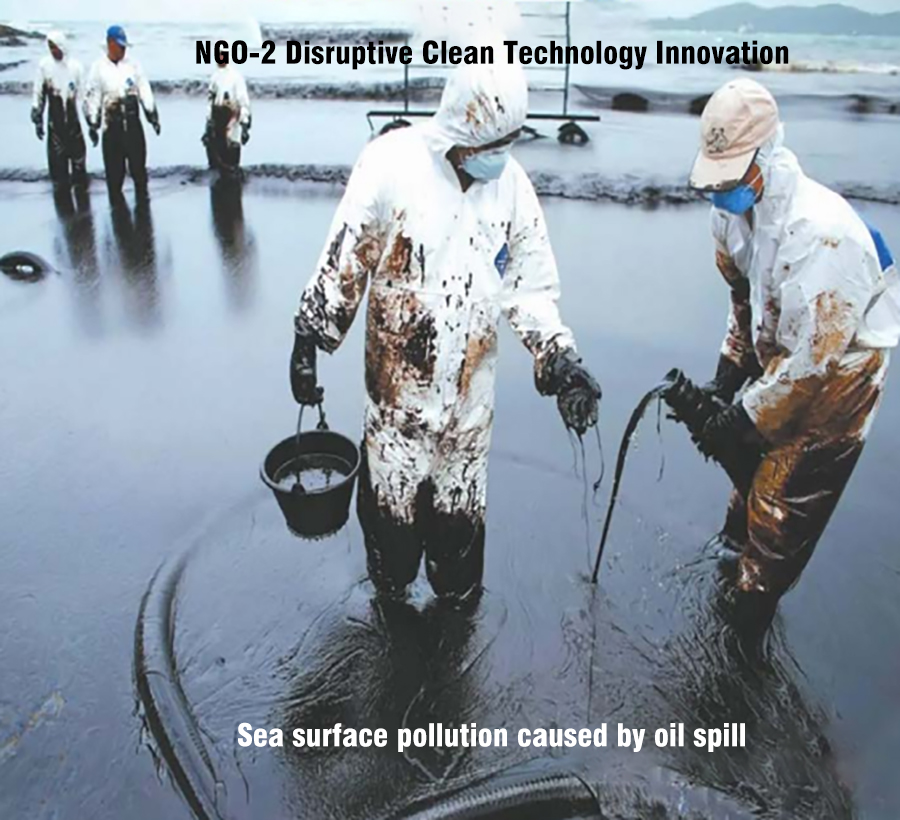

It is used for the recovery and disposal of ground crude oil, tank bottom oil sludge, ground oil spill, refinery oily sludge, etc.

It is estimated that there are 9 billion tons of oily sludge and waste liquid contaminated by heavy oil in the world, and it is increasing every year. The oil-bearing mud and sand mixture is mainly caused by the leakage of crude oil exploration and production, crude oil transfer fluid, oil pipeline, refinery, crude oil storage tank bottom, petrochemical plant, crude oil wharf, oil tanker, merchant ship, etc. Traditional processing methods are basically used.

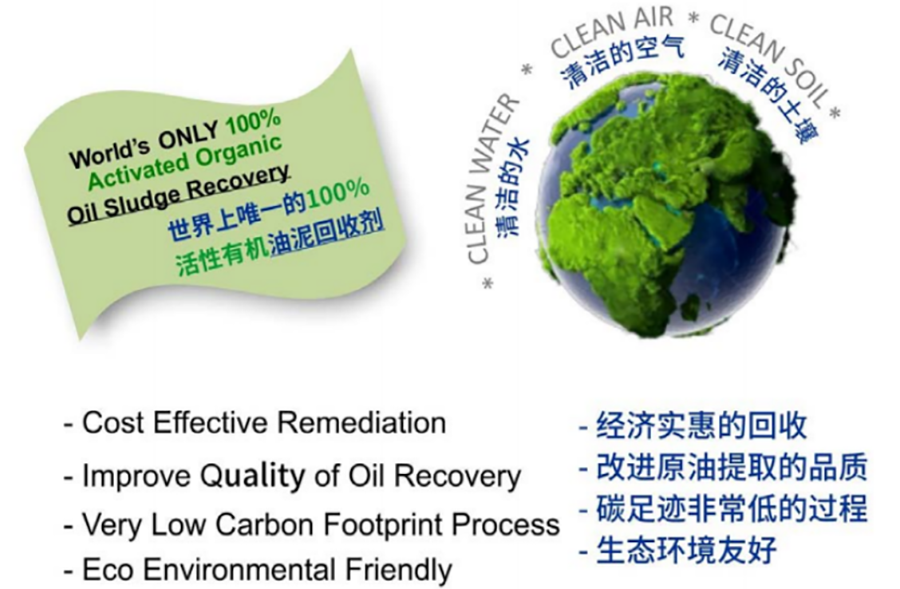

Chemical surfactant has the advantage of low cost, but its use is limited because it is harmful to the environment, and it is difficult to biodegrade and pollute the environment. NGO-OG2 is a green product, which is mainly based on natural plant matrix and its derivatives. It can effectively separate crude oil from water and silt. Thereby playing a role in preventing accidental leakage.

The petroleum is recycled and is a biodegradable nano heavy plasticizer.

At present, the treatment and disposal technology of oily sludge is developing rapidly, and a variety of oily sludge treatment methods, such as conditioning and separation, chemical thermal washing, pyrolysis and incineration, have been applied to oil and gas fields and refineries in China. Under the strong impetus of stricter environmental protection, China's oil and gas field exploitation industry has increased the progress of oily sludge treatment. Due to the huge amount of oily sludge left over from history and its complex composition, the treatment capacity of oily sludge in China is far from meeting the demand for oily sludge treatment in the short term, and the huge market cake attracts a large number of cross-border capital to turn to the oily sludge disposal industry. The domestic oil sludge output increases from 7.349 million tons in 2014 to 7.793 million tons in 2022, with a compound annual growth rate of 0.74%, the domestic oil sludge disposal volume increases from 3.076 million tons in 2014 to 5.883 million tons in 2022, with a compound annual growth rate of 8.44%. In terms of production and treatment capacity alone, the domestic treatment rate has increased significantly, but in the face of hundreds of millions of tons of historical stock, there is great room for growth in China's sludge treatment industry.

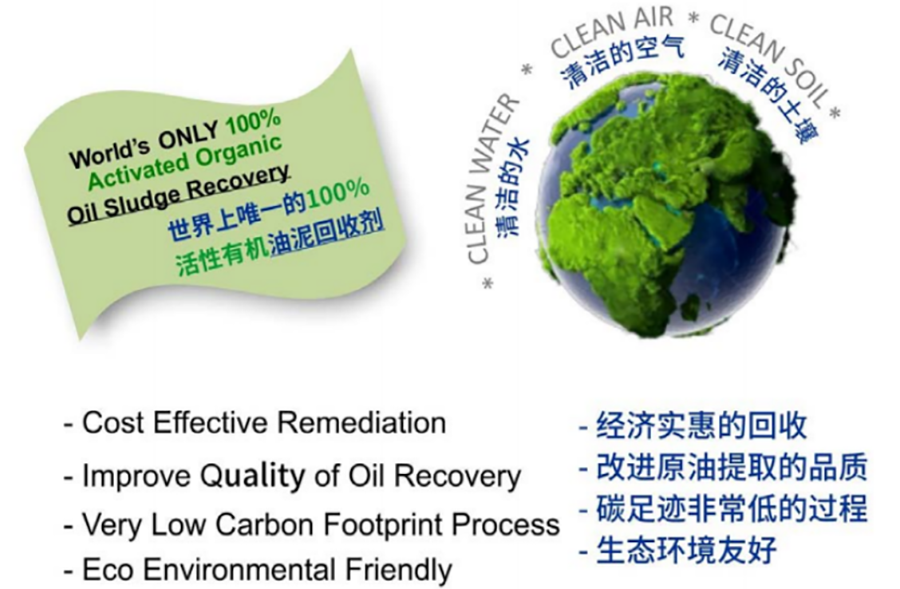

Organic oily sludge disposal technology products are the latest generation of oily sludge disposal products developed for the current status of oily sludge disposal technology.

Product technical features:

★ Based on natural plant matrix and its derivatives ★ Active organic products

★ Biodegradable nano crude oil remodeling ★ The product will not cause any toxicity to water, soil and the environment

★ Non-corrosive, non-flammable, non-hazardous, non-toxic chemicals

NGO-2 active organic oil sludge recovery agent

Current situation

Globally, there are an estimated 9 billion tons of liquid waste contaminated with heavy oil (increasing every year)

The source of oil sludge is:

· Crude oil exploration and production

· Crude oil drilling fluid

· Oil pipelines

· Refinery (100,000b/d = 50t sludge/year)

· Bottom of crude oil storage tank

· Petrochemical plant

· Oil storage station

· Tanker

· Merchant marine fuel tanks

Use of chemical surfactants for recovery

One of the most effective recovery processes for extracting oil from dirty oil is the use of chemical surfactants. The use of chemical surfactants is fast and cost effective, however, it is of great concern because it is environmentally toxic and difficult to biodegrade.

At present, the market basically uses chemical agents to treat sludge recovery, which is toxic to the links and can not be biodegraded, and belongs to the hazardous waste industry.

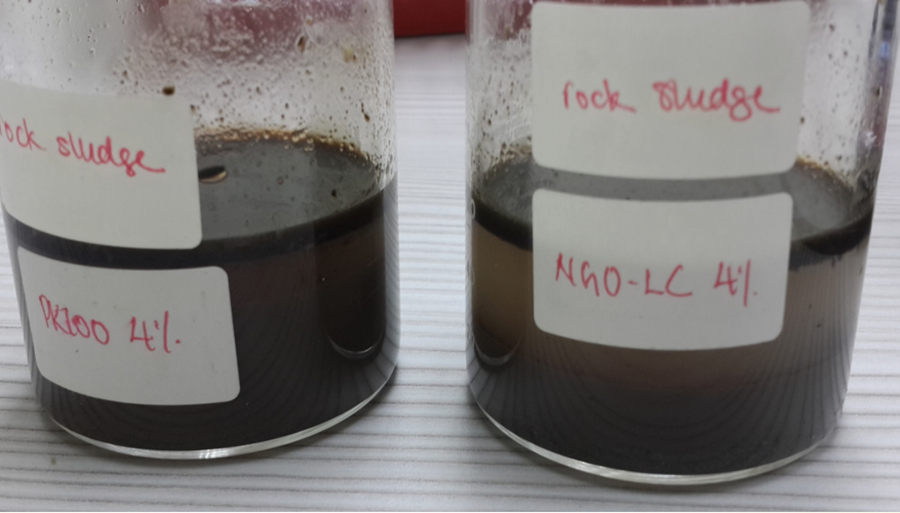

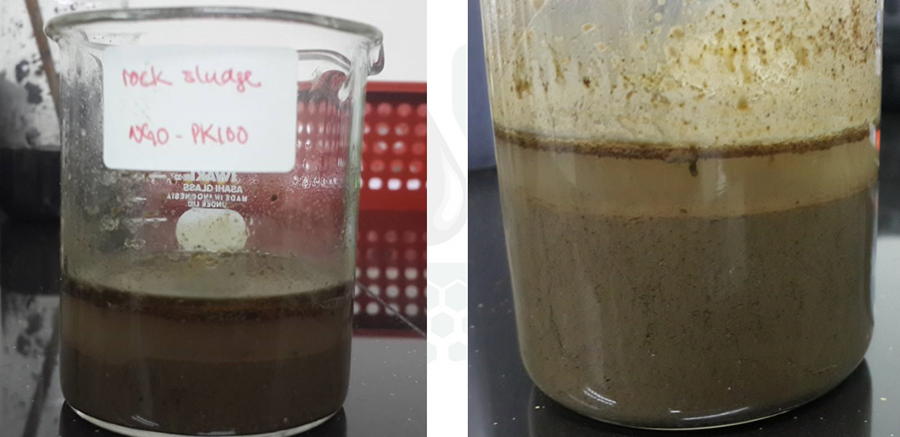

NGO-2 is tailor-made to break down long hydrocarbon bonds. It selectively breaks down hydrocarbon molecular chains and promotes crude oil.

The viscosity is effectively reduced, and the high-viscosity tar sand or asphaltene sludge is effectively separated.

Oily sludge is a kind of oily solid waste produced in the process of oil exploitation, transportation, refining and oily sewage treatment, and it is one of the main pollutants produced in the process of oil and gas development, storage and transportation. Oily sludge contains a large number of toxic substances such as benzene series and phenols, but these substances are also components of crude oil. Oily sludge is not only a waste produced in the process of oilfield production, but also a resource. If oily sludge is not treated to recover its oil, it will not only pollute the environment, but also cause waste of resources. For many years, the disposal method of oily sludge in the oilfield area of our country is basically the landfill of abandoned oil pits, and the non-standard abandonment and disposal process has great potential environmental pollution. The environmental protection treatment of oily sludge and the recovery of residual oil by using the active organic sludge recovery technology of all-living NGO will not only produce certain economic benefits, but also reduce pollution, and bring huge environmental and social benefits.

Technical characteristics of NGO and products

• NGO-2 is a fully biodegradable organic material.

• In case of leakage or accidental discharge at the use site, NGO-2 will not cause any pollution and toxicity to water, soil and environment.

• The residues of NGO-2 in the tailings pond will not cause any toxicity.

• The application of NGO-2 technology can significantly improve the reaction rate and separation rate. In other words-reduce processing time and increase recovery.

• NGO-2 is tailor-made for the decomposition of long hydrocarbon bonds. It selectively decomposes this molecular chain to effectively reduce the viscosity of the treated oil. The application of NGO technology can also effectively separate the high-viscosity tar sand or asphaltene sludge.

• The application of NGO-2 technology can effectively improve the recovery rate of dirty oil, maximize the environmental protection and optimize the treatment process, and reduce the overall recovery cost.

Widespread use of NGO-2

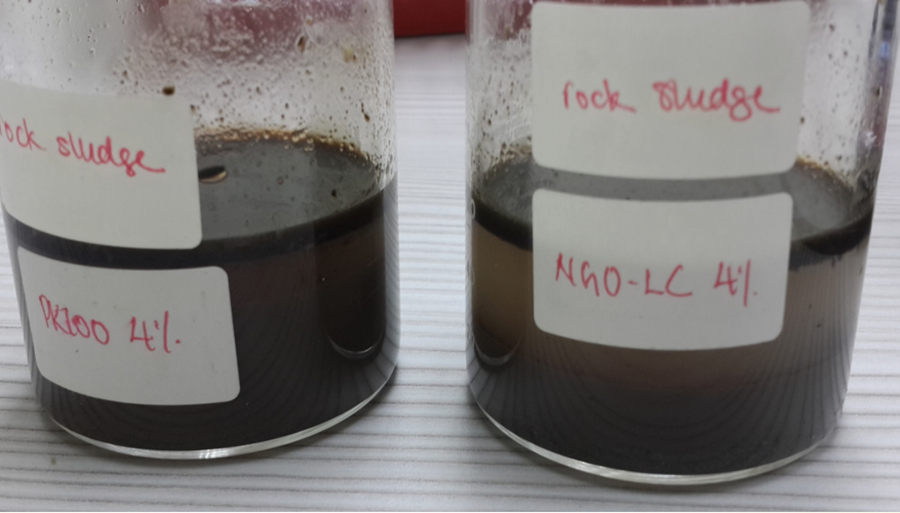

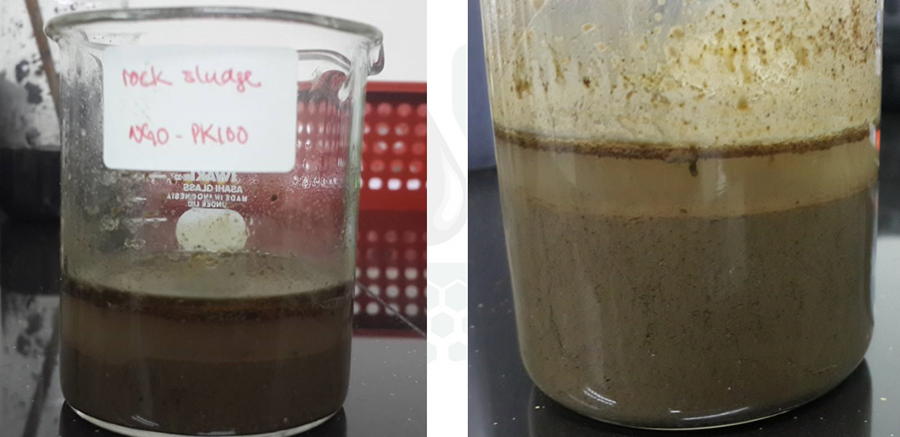

Picture of application test of NGO-2

Application prospect of that product

There is no doubt that China's growing demand for oil will have a significant impact on climate change, air quality and people's quality of life. The carbon footprint left by oil is obvious. With the increase of oil consumption, the expansion of overseas oil investment and the improvement of capacity, China will play a key role in the Asian and global oil product market.

Even if economic growth slows, China's oil consumption will continue to grow at an annual rate of about 5%. To meet this demand, China will have to use "dirty oil" that is cheaper but more harmful to the environment, such as oil sludge. Without new regulations that take climate change or a carbon tax into account, China's growing oil demand will have a significant negative impact on air quality and climate change.

Another major environmental challenge facing China is water, which is an indispensable resource when extracting heavy oil through fracturing. Therefore, the development of unconventional oil will have to compete with agricultural, industrial and urban users for limited water resources. In addition, the treatment of oily water in the fracturing process is also a difficult problem for China.

There are more than 3000 kinds of auxiliaries and additives used in oil field exploitation, gathering and transportation, refining, production of refined oil, fuel oil and deep processing of fine chemical products, many of which are toxic, harmful, environmentally polluting and non-degradable products, which will cause a large number of hazardous wastes after use. Promoting the use of environmentally friendly, degradable and pollution-free petroleum additives is the best way at present, and the state is also introducing various promotion policies. At present, the NGO active nano-biological petroleum additives produced by Wanwusheng Company can be used in the whole industry chain of petroleum processing, and they are environmentally friendly, pollution-free, biodegradable and will not cause secondary pollution in the use process. The future market development and application prospects are huge.

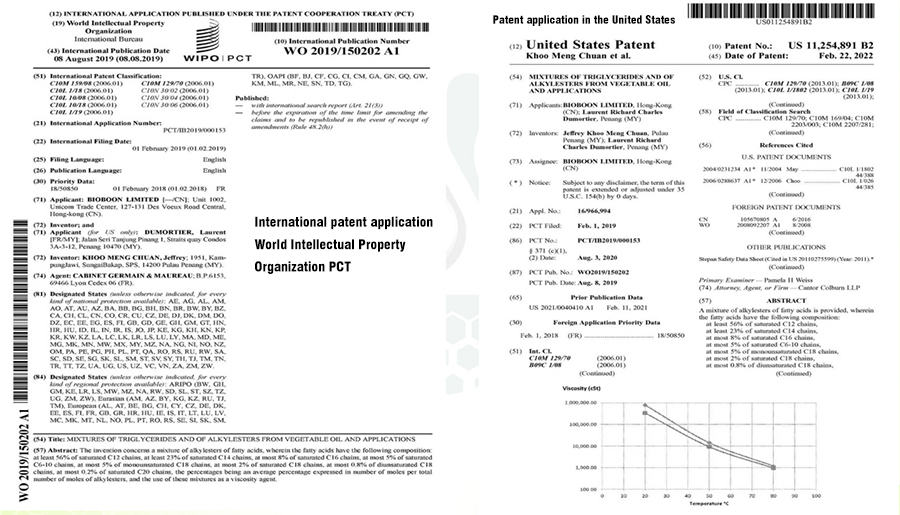

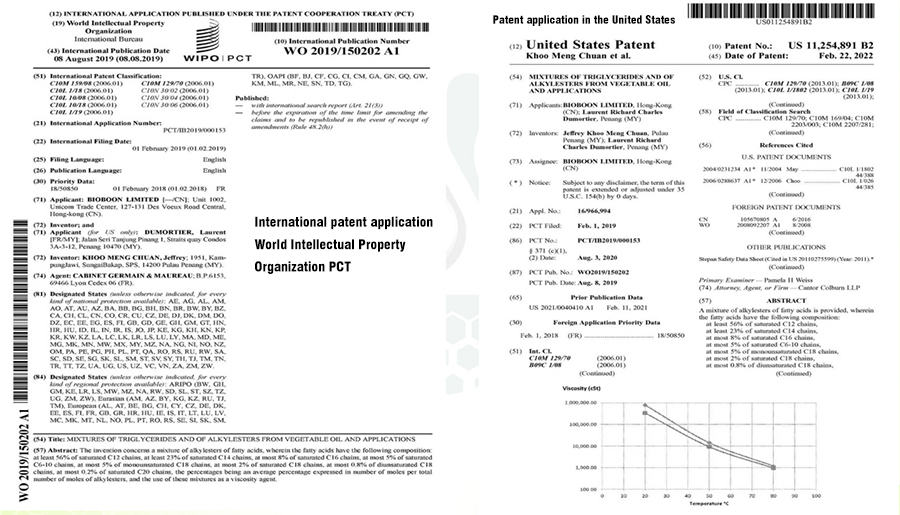

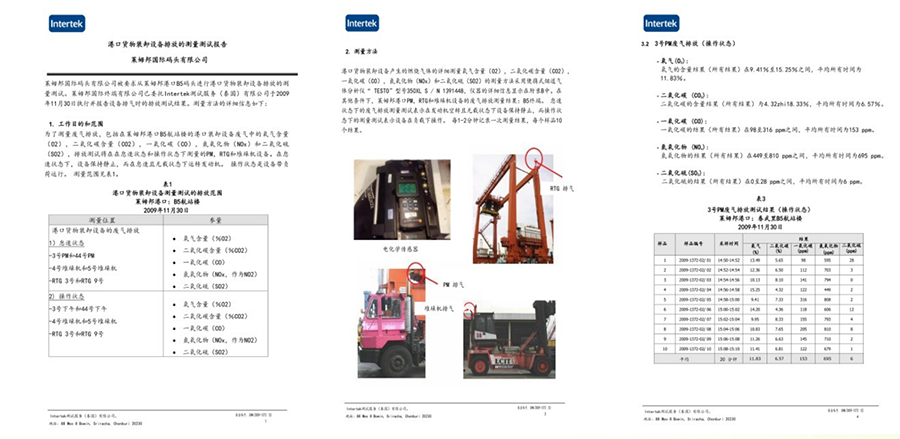

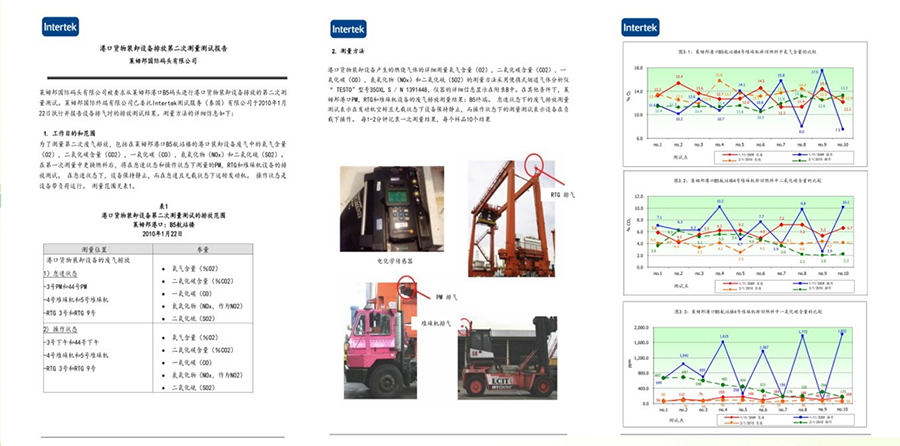

Patent report