Enterprise profile

Shenzhen NGI Bio-Aid Petroleum EnviroTech Co., Ltd., founded on 02 January 2020 with a factory area of 1500 square meters, is a modern innovative biotech High-tech Enterprise integrating R & D, production and sales.

After years of technical research and innovation, we succeed in developing and mass producing NGO series of products: bio-based nano-active petroleum bio-additives, with independent intellectual property rights under our own brand, which have excellent environmental performance and can be completely biodegradable, filling the market gap of green and environmentally friendly petroleum additives at home and abroad. The products have been successfully put into use in China, Mexico and Colombia, and we have signed strategic cooperation agreements with agents in Angola, Venezuela and Turkmenistan. We also actively cooperate with many domestic oil production companies such as Shengli Oilfield, Tuha Oilfield, Liaohe Oilfield, and Daqing Oilfield.

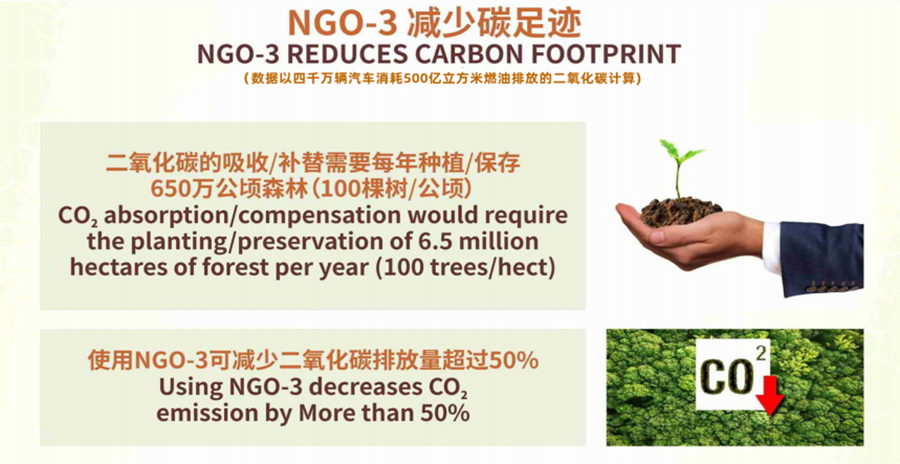

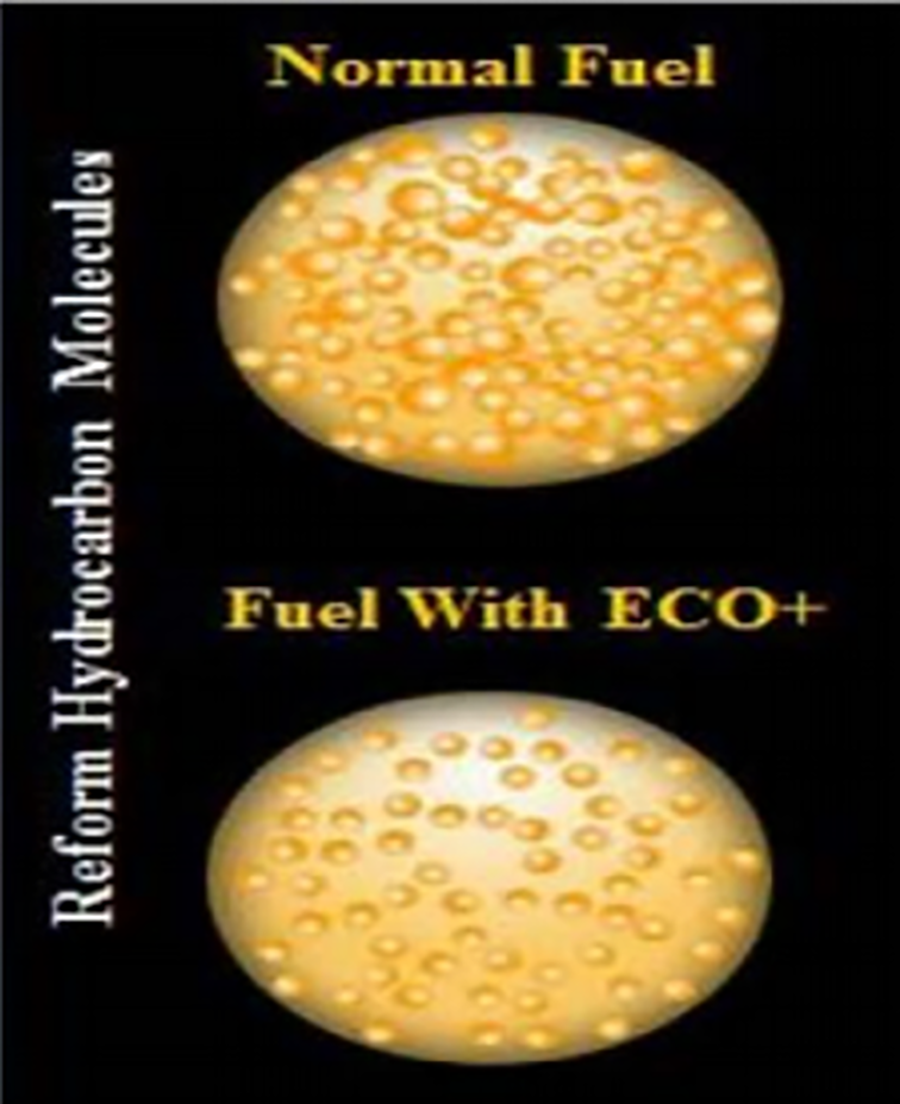

NGO series of products, totally different from various chemical synthesis petroleum additives which are the mainstream in current market, are completely biodegradable and environmentally friendly nano-scale petroleum reforming agent. It can quickly penetrate into the molecular chain of petroleum, break down the molecular chain of excessively large hydrocarbon molecules in petroleum, reform and homogenize clustered hydrocarbon molecules of different sizes, fundamentally improve the quality of crude oil, and significantly improve the performance of crude oil in all aspects including mining, refining, storage, transportation, use, and environmental management, besides substantially reduce production costs and carbon emissions.

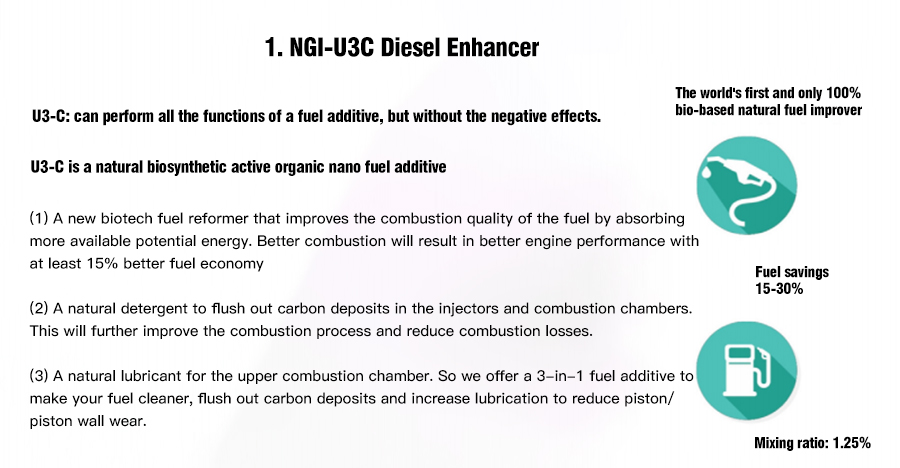

Product overview

NGO3 fuel oil cleaning synergistic catalyst

A revolutionary product of fuel additive technology

Bio-based nano active environment-friendly degradable

• Completely soluble in fuel oil, can be directly added to refinery blending tanks, product oil storage tanks, gas station storage tanks, ship fuel storage tanks, heavy oil storage tanks.

• It can be directly added into the fuel oil tanks of diesel generator sets of trucks, automobiles, ships, diesel generator sets, eNGOneering machinery, military equipment, etc.

• Remove gum and inhibit the generation of carbon deposits.

• Improve the fuel quality, clean oil circuit and reduce the fuel consumption.

• Improve fuel lubricity and extend eNGOne life.

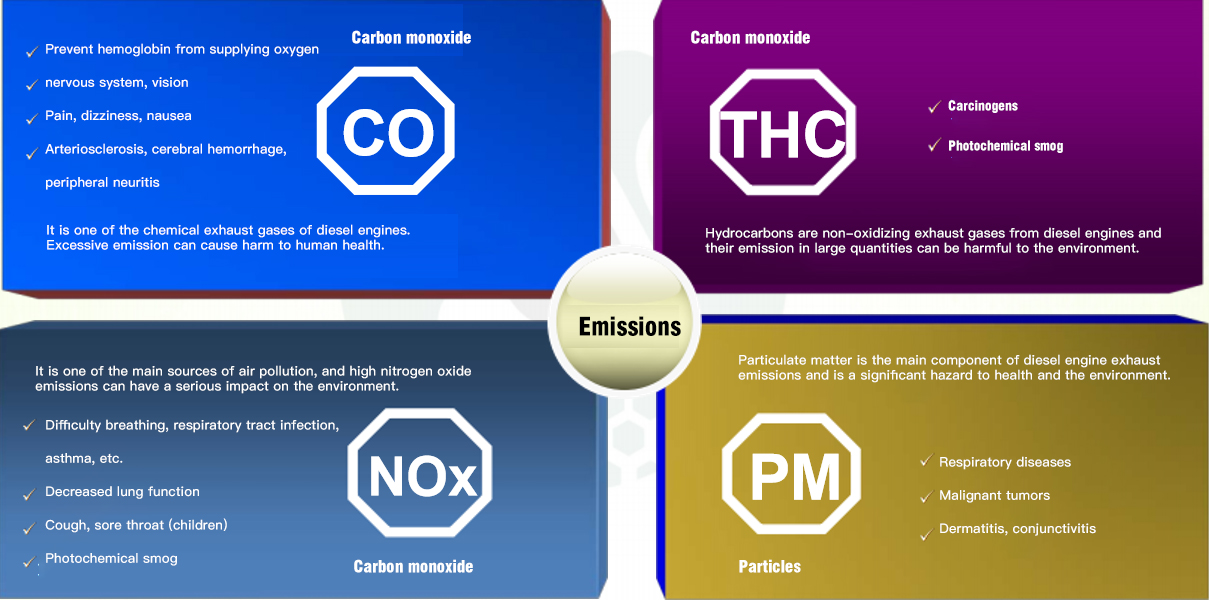

• Reduce NOx, CO, HC and PM emissions.

The sixth generation of fuel additives, the world's only natural active biodegradable products.

Product characteristics of NGO3 fuel detergent synergist

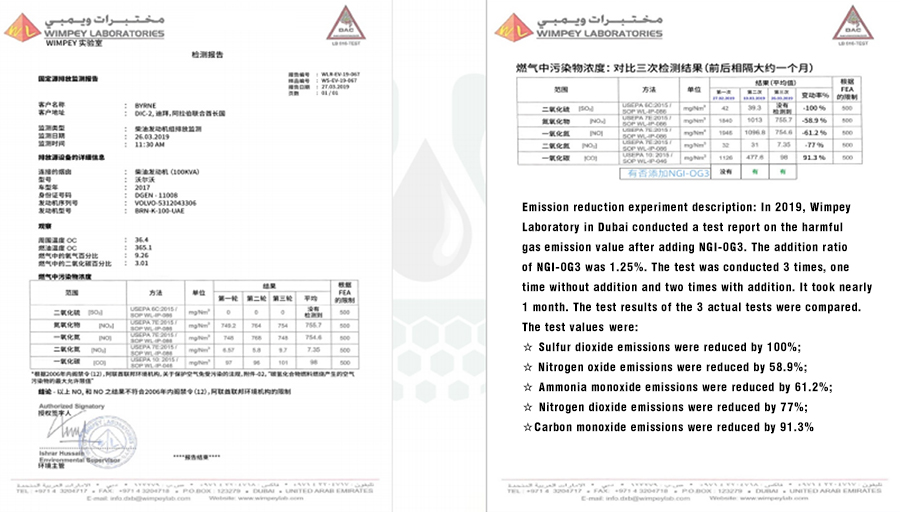

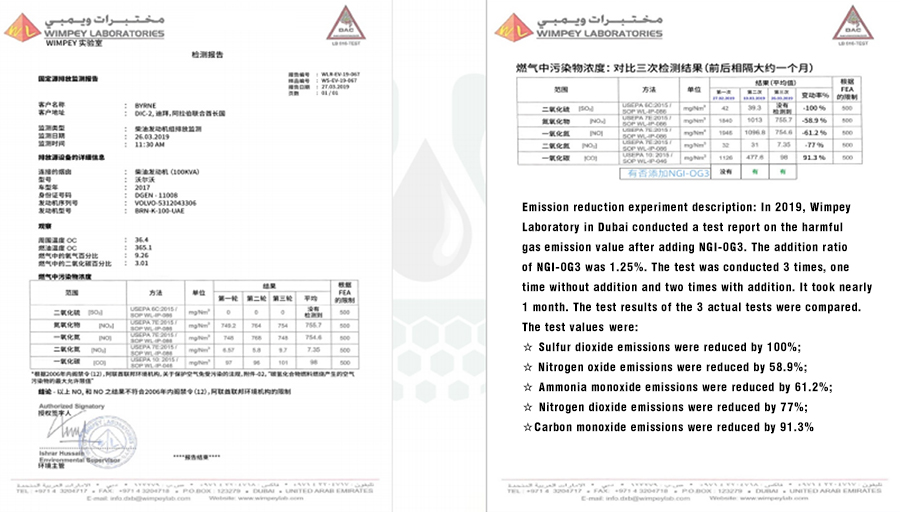

Emission Test Report of Diesel ENGOne Unit, WIMPEY Laboratory, Dubai

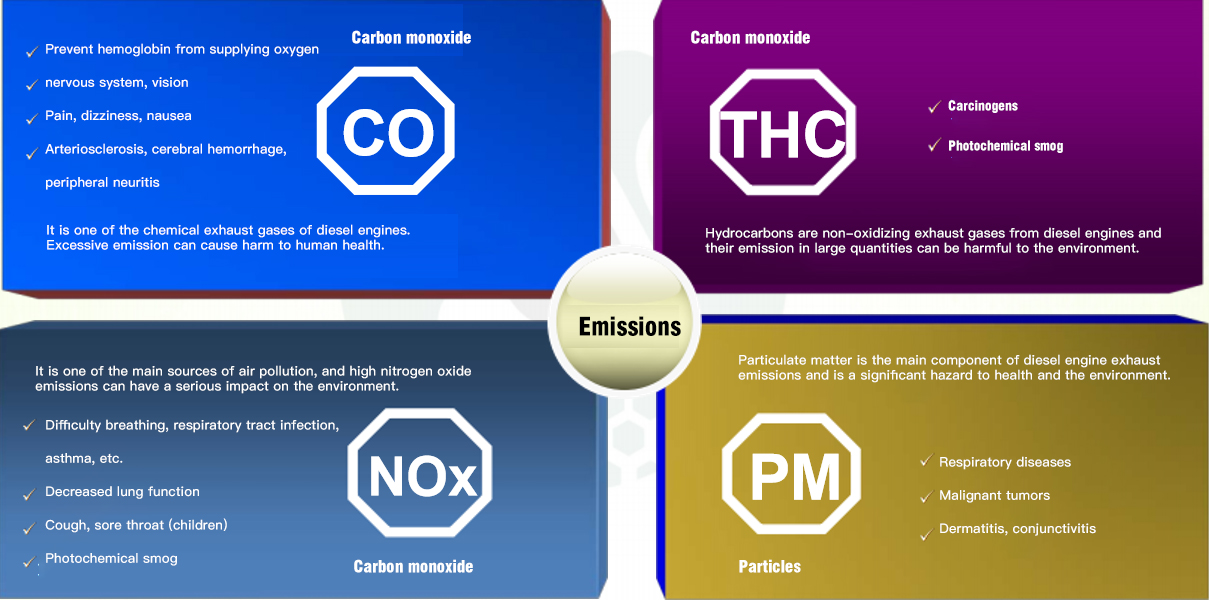

Hazards of eNGOne emission pollutants

Method for removing pollutant discharged by diesel eNGOne

Contaminants | Main ingredients and sources | Method for purifying and removing combustion in machine | Primary aftertreatment system |

Hydrocarbon (THC) | Unburned fuel, too thin or too thick lubricating oil mixture, nozzle leakage, cold working condition, abnormal injection, etc. | Nozzle design, injection parameter optimization, NGO3 active organic nano fuel cleaning synergistic catalyst added in the fuel | DOC (Diesel Oxidation Catalyst) |

Carbon monoxide (CO) | Partial oxygen deficiency, low temperature and insufficient reaction time of incomplete oxidation products of fuel oil | Improve mixing, optimize injection parameters, and add NGO3 active organic nano fuel cleaning synergistic catalyst into the fuel | DOC (Diesel Oxidation Catalyst) |

Nitrogen oxides

(NOx) | NO, NO2 and other high temperature, oxygen-rich diffusion combustion stage | EGR, reduce combustion temperature, optimize injection parameters, add NGO3 active organic nano fuel purification catalyst to fuel | SCR (Selective Reduction System) |

Particulate matter

(PM) | Soot, SOF, Sulfate, Ash Combustion Process, Oil Consumption, High Sulfur Fuel, ENGOne Wear | Improve combustion (mixing and optimization of injection parameters), reduce eNGOne oil consumption, use low-sulfur fuel, and add NGO3 active organic nano fuel cleaning synergistic catalyst in the fuel | DOC, POC (particulate oxidizer), DPF (particulate trap) |

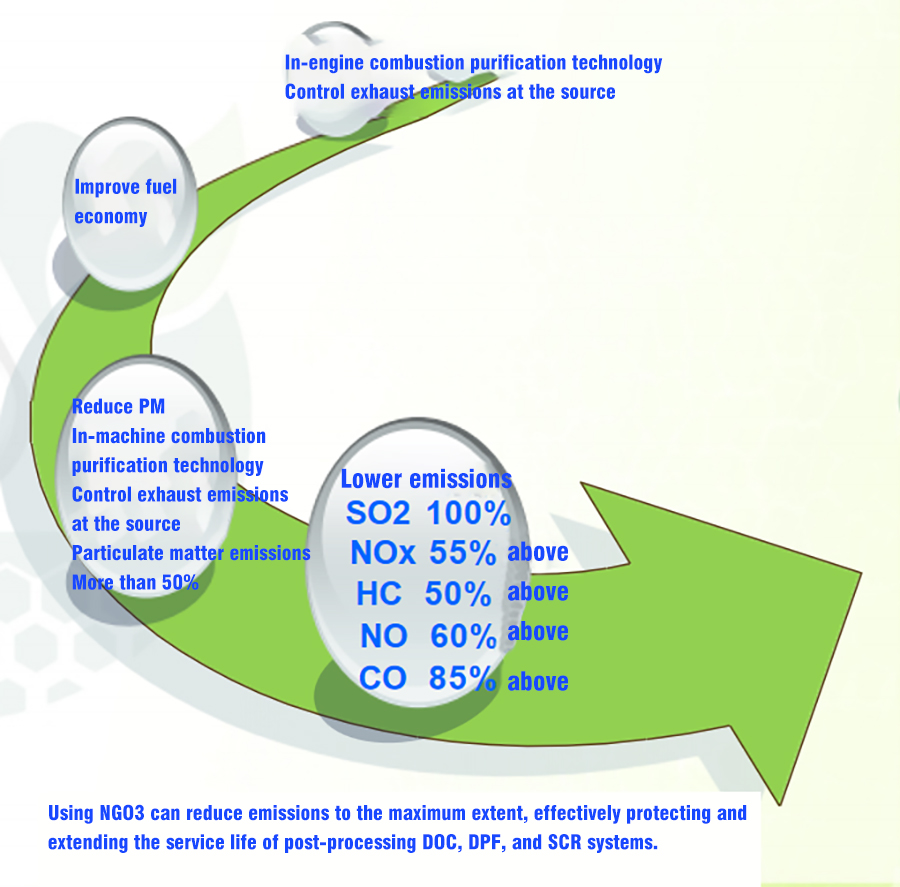

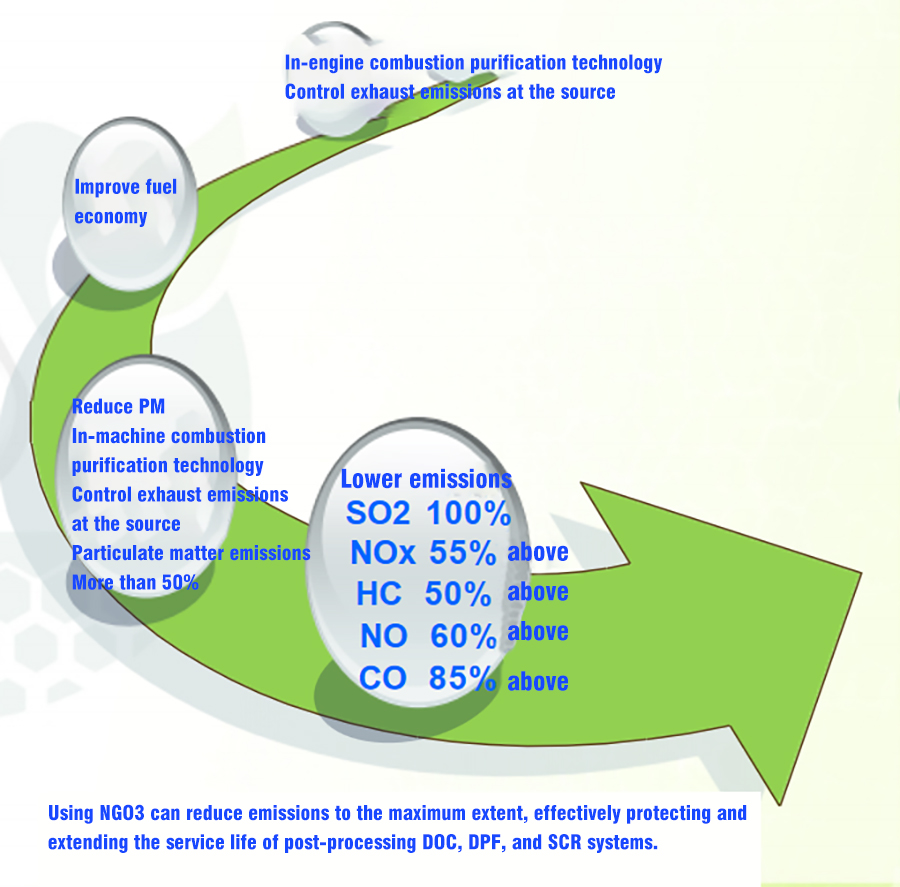

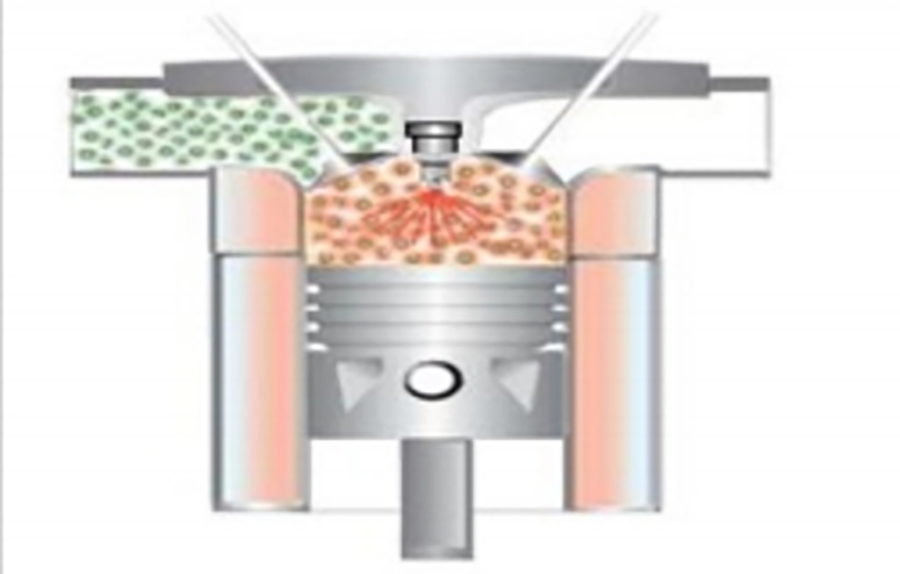

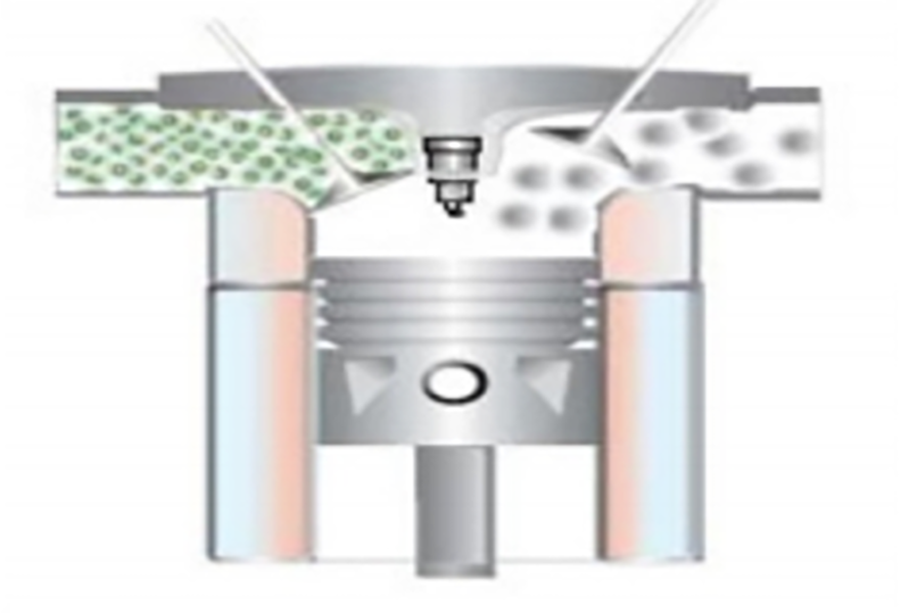

In-eNGOne combustion purification technology of NGO3 fuel oil purification synergistic catalyst

Classification of emission control methods

· Emission source control technology: also known as in-eNGOne combustion purification technology. For example, the key technology of eliminating the pollutants produced by fuel combustion in the process of converting fuel chemical energy into mechanical energy is to add NGO3 active organic nano-fuel purification synergistic catalyst, which is the most effective in-eNGOne combustion purification technology product at present.

· Emission after-treatment technology: It is a necessary measure for the current fuel vehicles to reduce the environmental hazards caused by the existing vehicle emissions, and the related technology is usually called emission after-treatment technology.

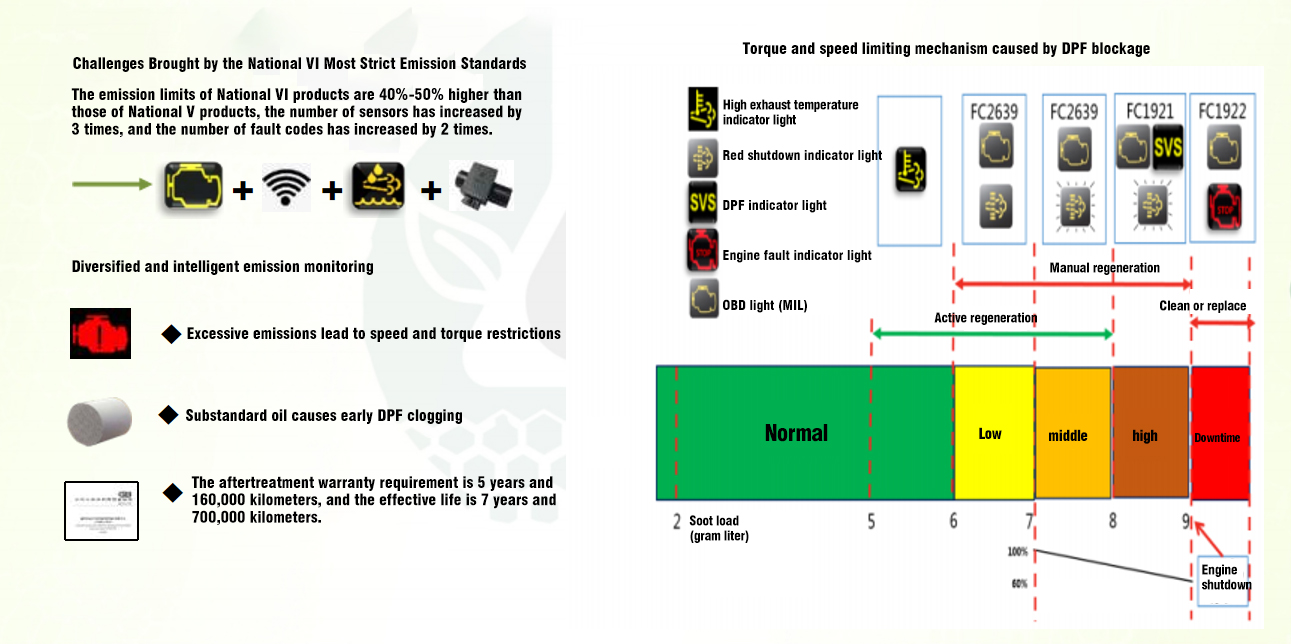

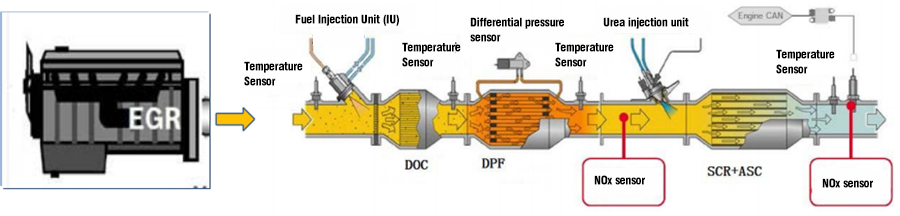

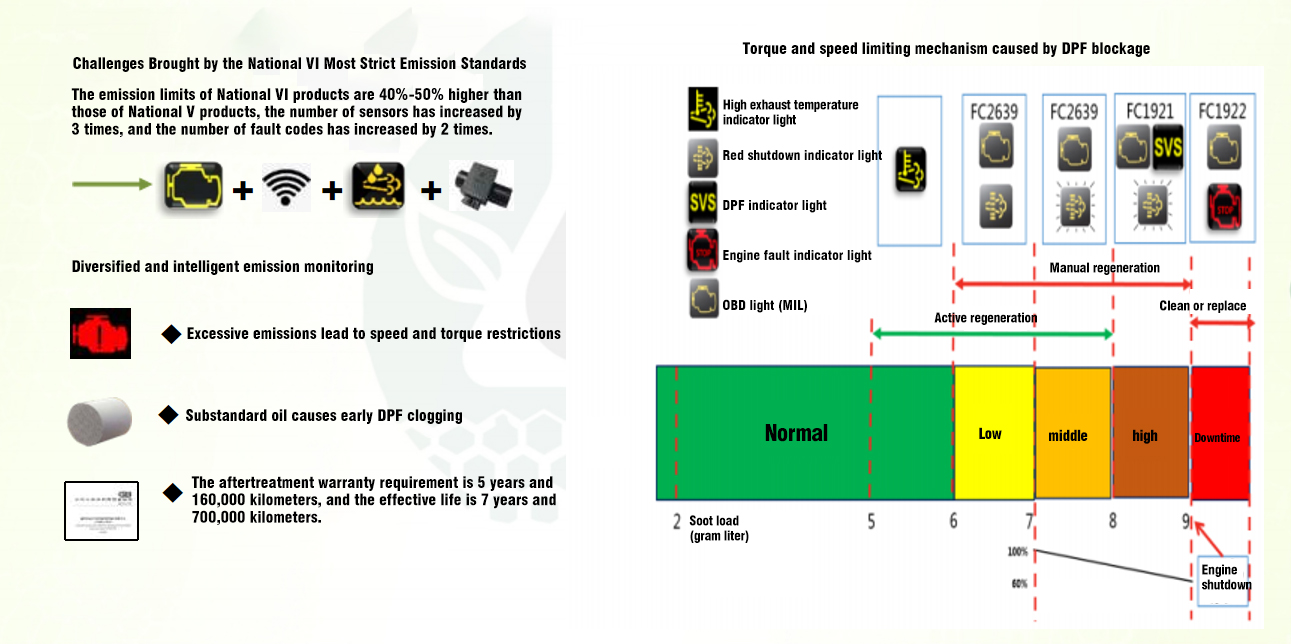

Introduction to China VI Technical Route

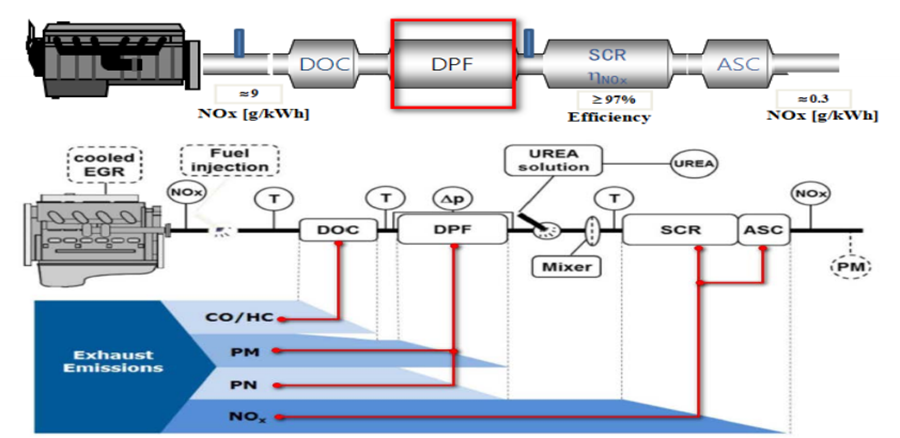

The proposal of the sixth national limit is known as the most stringent emission regulation in the world. In terms of technical route, the mainstream technical route adopts in-eNGOne combustion purification + ultra-high pressure common rail (the original 1600 Bar rises to 1800 or 2000 Bar). Fuel atomization burns more fully) + EGR (Nox emission control) + (DOC + DPF + SCR + ASC) aftertreatment technology route.

General Situation of Combustion and Purification Technology in ENGOne

The core of diesel eNGOne combustion purification technology is to optimize the combustion process, starting from the generation mechanism and influencing factors of harmful emissions, to enhance fuel quality and improve the eNGOne combustion process as the core, to reduce and inhibit the generation of pollutants.

At present, China VI (Euro VI) emission standard is the most stringent emission standard in the world, especially the China VI B emission standard is stricter than Euro VI emission standard. The refining technology of existing refineries at home and abroad has been very advanced, and the quality standards of gasoline and diesel produced by refining are fully in line with the China VI standard. It is very difficult to improve the quality standard of gasoline and diesel in order to reduce emissions. In order to reduce the emissions of PM, NOx, CO, THC and other harmful substances, adding clean synergistic catalyst in fuel is the most effective and feasible way to reduce eNGOne pollution.

In-eNGOne combustion purification technology for pollutants emission.

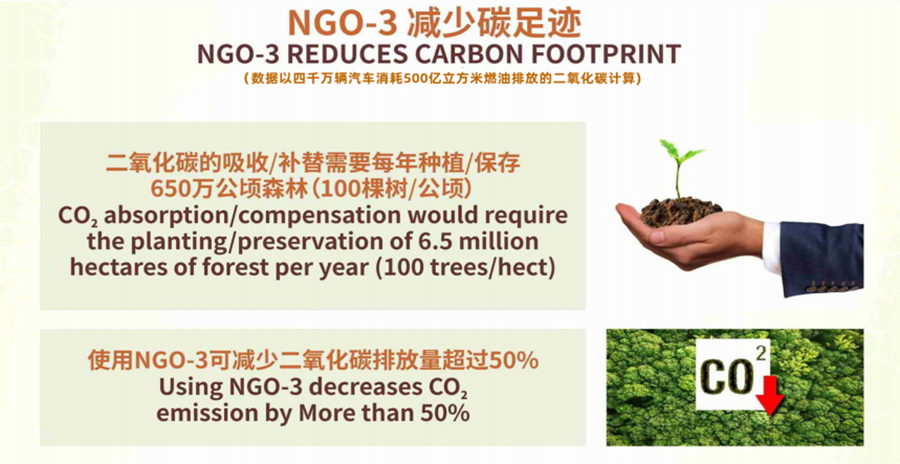

The biobased active organic nano fuel oil cleaning synergistic catalyst is the only green environment-friendly degradable product at home and abroad at present, has the important characteristic that the active nano organic product of biomass can be completely biodegraded, is a nano fuel oil remodeling catalyst, can quickly penetrate into the molecular chain of the fuel oil, Chains of the reformed fuel oil hydrocarbon are decomposed, and cluster-shaped hydrocarbon molecules of different sizes are reformed and homogenized, so that the quality of the fuel oil is improved, the performance requirements of an eNGOne are met, the fuel oil molecules become smaller and more homogeneous, the atomization effect and the aerobic combustion efficiency of the fuel oil are improved, and the fuel oil is combusted cleanly. The emissions of sulfur dioxide, nitrogen oxides, carbon monoxide, hydrocarbons and particulate matter have been greatly reduced.

Diesel eNGOne emission

For emissions, all currently available technologies are applied

NGO3 Fuel Additive Product Application Classification

A. has the characteristics of reforming and homogenizing fuel hydrocarbon molecular chains

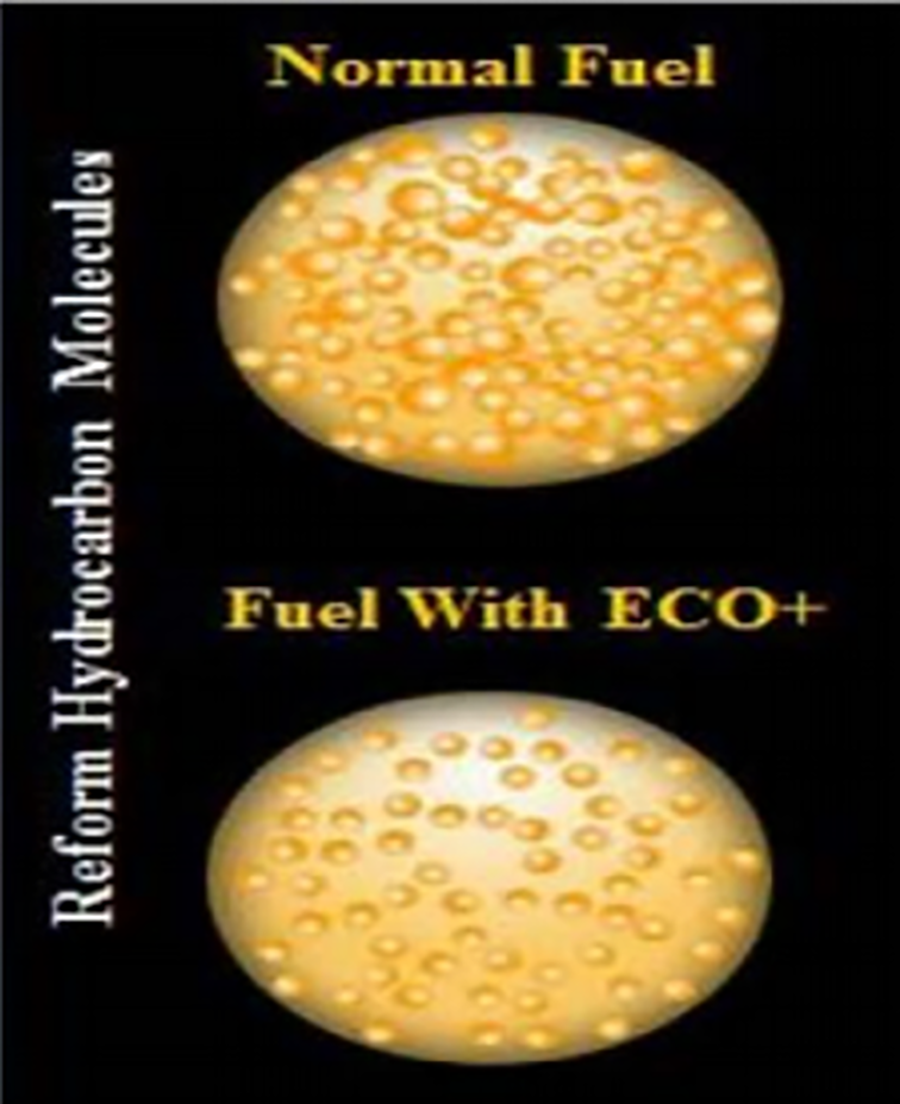

Characteristics of typical oil droplet

Typical fuel droplets are made up of hydrocarbon molecules of varying sizes, which also tend to clump together to form larger fragments, preventing complete combustion.

U3-C Reform Fuel

Cluster hydrocarbon molecules of different sizes are reformed and homogenized to improve fuel quality and meet eNGOne performance requirements.

Finer formulation of fuel molecules

The fuel becomes finer, more uniform, and has increased cleaning and lubricating properties. Improved fuel quality also results in better, more complete combustion.

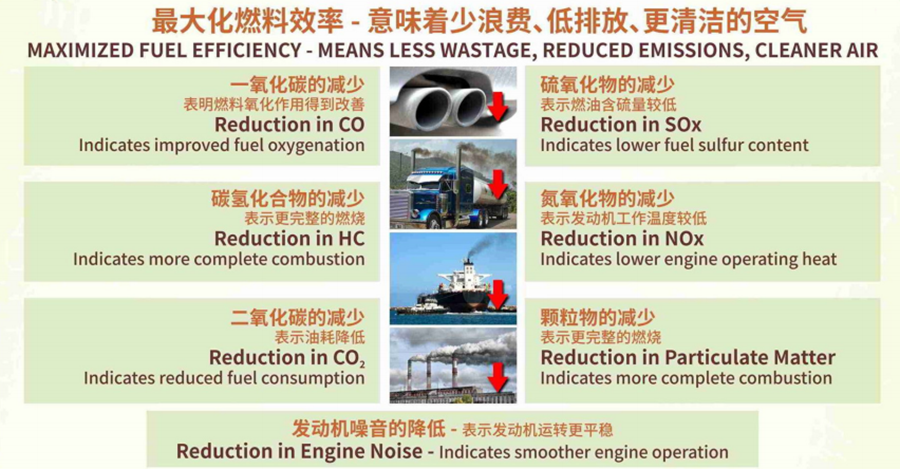

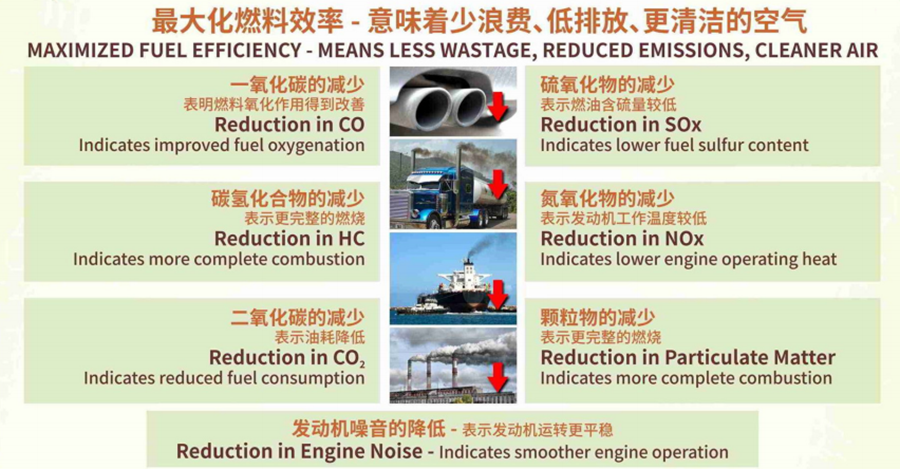

B. can maximize fuel quality

Maximized combustion efficiency makes full use of the fuel's potential

· More complete combustion means ultra-low emissions

· More complete combustion means maximum use of fuel energy while reducing waste

More complete combustion means higher energy conversion and higher performance

· Even power delivery means smoother eNGOne operation

Maximized fuel detergency and fuel lubricity

· Reduce the friction and wear of piston, ring and bushing

· Clean fuel system and the upper compartment

· Lower upper chamber operating temperature means less eNGOne knock

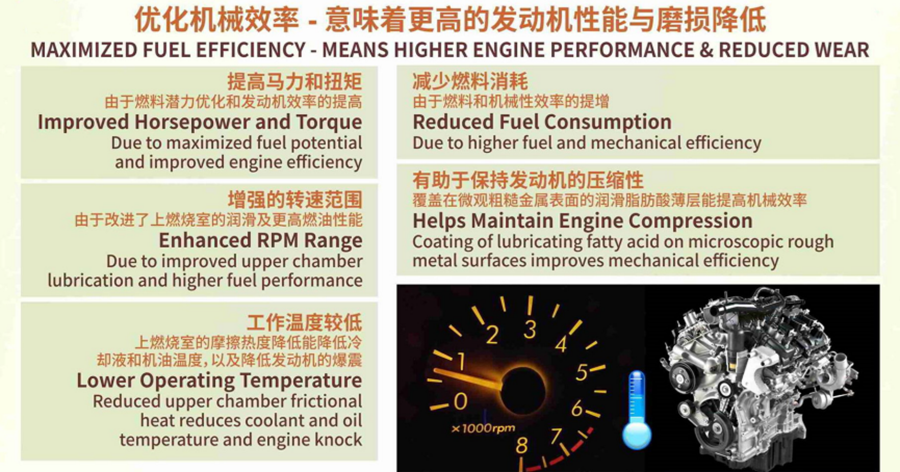

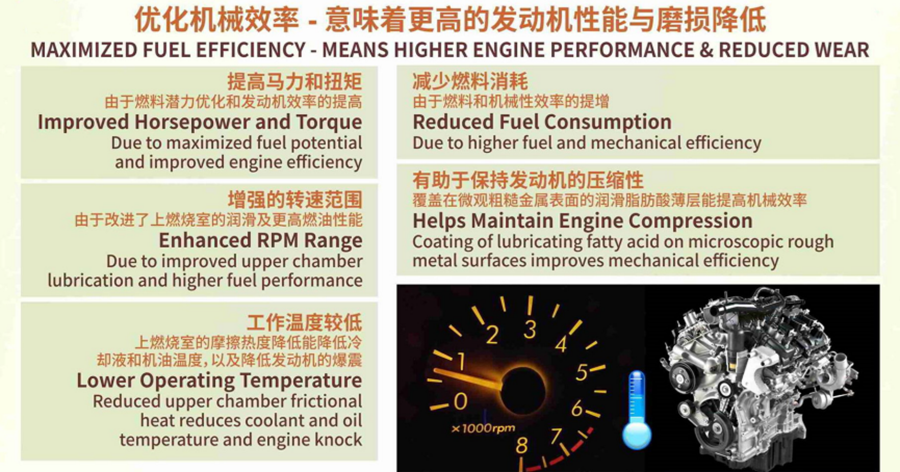

C. Reduce eNGOne wear and improve eNGOne performance

Increased horsepower and torque

Maximum fuel potential and improved eNGOne efficiency

Enhanced RPM Range

This is due to improved lubrication of the upper chamber and higher fuel performance

Lower operating temperatures

Reducing the friction heat in the upper cavity helps to reduce coolant and oil temperatures and eNGOne knock

Reduce fuel consumption

This is due to higher fuel and mechanical efficiency

Helps maintain eNGOne compression

Coating lubricating fatty acids on microscopically rough metal surfaces improves mechanical efficiency

D. The sixth generation fuel additive with advanced technology and performance

Finer, more uniform fuel molecules improve fuel atomization and fuel efficiency

More complete combustion reduces carbon monoxide, hydrocarbons, and particulate matter. Less fuel usage reduces overall CO2

NGO + enables cleaner combustion. The cleaning effect keeps valves, pistons, and walls free of carbon deposits. Lubricates piston walls, reduces frictional heat and wear, and improves mechanical properties.

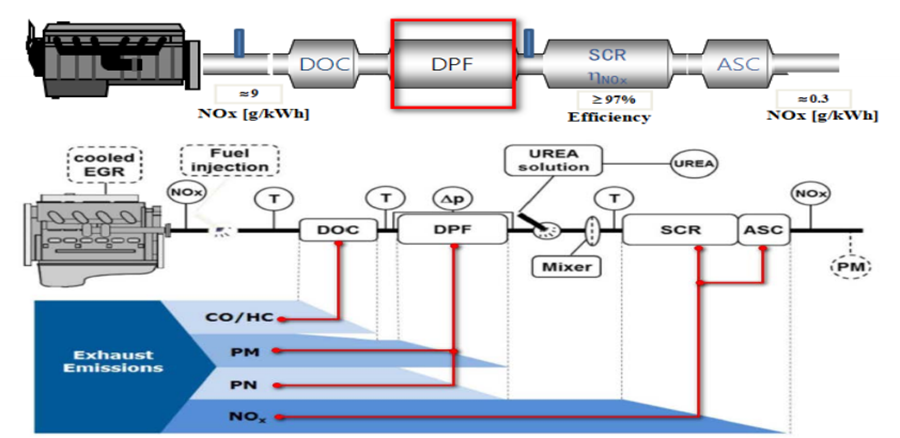

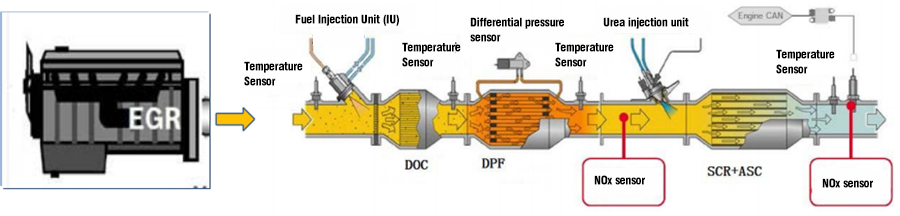

Technical Route and System Architecture of China VI Post-processing System

The aftertreatment system consists of the following components:

√ Catalytic converter: DOC + SCR + ASC

√ Particulate Trap: DPF

√ Urea supply unit, injection unit

√ Fuel metering unit, injection unit

√ Sensor: temperature sensor, nitrogen oxygen sensor, differential pressure sensor, PM sensor

In addition to stricter regulations on NOx and PM emissions, China VI also stipulates emission limits for CO, HC and NH3, and will also increase the monitoring of PM emissions. The generation conditions of NOx and PM are contradictory. When the NOx value is reduced by the EGR system, the emission of PM particulate matter will increase. In order to deal with the emission of PM particulate matter, the above system adds a DPF (particulate matter trap) in the aftertreatment to deal with and trap PM.

However, when the DPF captures a certain amount of PM (carbon load), it needs to increase the exhaust temperature to regenerate the DPF, so the DPM (Bosch HCI injection system) is added to inject a certain amount of fuel into the exhaust pipe during regeneration to increase the regeneration temperature of the DPF.

The addition of NGO3 plays an important role in the maintenance of the after-treatment system of the fuel vehicle.

The addition of NGO3 active organic nano fuel cleaning synergistic catalyst in fuel can minimize the emission of harmful substances, reduce the workload of DOC, DPF and SCR of aftertreatment system, save the maintenance cost of aftertreatment system and prolong the service life of aftertreatment.

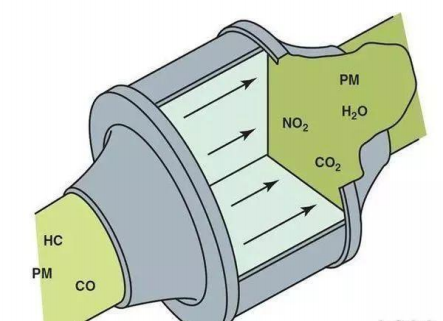

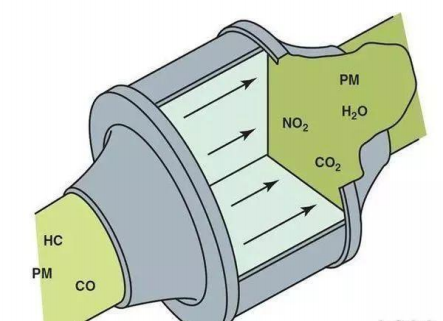

DOC (Diesel Oxidation Catalyst)

The full name of DOC is Diesel oxidation catalyst, which is the first step of the whole after-treatment process. It is usually the first section of the three-section exhaust pipe. It usually uses precious metal or ceramic as the catalyst carrier. The main function of DOC is to oxidize CO and HC in the exhaust gas and convert them into non-toxic and harmless CO2 and H2O. At the same time, it can also absorb soluble organic components and some carbon particles, and reduce the emission of some PM. And oxidizes no to NO2 (NO2 is also a source gas of the lower reaction).

Schematic Diagram of DOC Oxidation Process

NGO3 — the world's leading in-eNGOne combustion purification DPF system technology product

NGO3 active organic nano fuel cleaning synergistic catalyst is an environmentally friendly and effective eNGOne emission combustion purification technology product, which can effectively reduce and remove ash, sulfate, soot particles, colloidal carbon polymer and other blockages in the aftertreatment system, greatly reduce harmful exhaust emissions, and greatly save the maintenance cost of the eNGOne aftertreatment system. Reduce fuel consumption, restore power, and avoid excessive cost investment caused by serious blockage repair or replacement of DPF system.

Cause of DPF clogging

★ Abnormal blockage (the mileage to be dedusted is greatly shortened, and regular dedusting is required according to the situation to reduce exhaust resistance and reduce fuel consumption)

Clogging of DPF due to use of substandard oil:

1. Some private oil is used, and the sulfur content of private oil exceeds the standard seriously. The poisoned catalyst cannot be regenerated, thus aggravating the blockage.

2. The oil that does not reach the grade will greatly shorten the mileage of dust removal.

Initial use problems indirectly aggravate clogging:

1. The driver does not know how to regenerate in situ, resulting in DPF blockage.

2. Blockage caused by not doing in-situ regeneration for fear of oil consumption

★ Normal clogging: DPF clogging can be easily caused by long-time idling, low-speed driving and a large number of short-distance driving. Because in these cases, the temperature of the exhaust gas is difficult to reach the temperature of DPF combustion, resulting in particles can not be burned, and the accumulation of ash in the DPF, ash can not be actively removed, eventually leading to blockage, accumulation to a certain extent requires manual removal.

Manifestation of clogged DPF

Whether the DPF has been blocked can be judged by the following performance:

1. The fuel consumption of the vehicle increases and the power decreases.

2. The eNGOne works abnormally, the fault code appears, and the warning light is on.

3. Long-term failure such as failure to start the eNGOne.