Products for crude oil production increase, thick oil viscosity reduction and oily sewage treatment

1. Organic nano-liquid oil displacement agent for NGO: It is an oil displacement additive for increasing crude oil production in offshore and onshore oil fields at home and abroad.

2. that organic nano thicken oil viscosity reducer with the life activity of NGO is used for the production of the thickened oil, the storage of the thickened oil and the collection and transportation of the thicken oil.

3. Organic nano ground oil recovery treatment agent: It is suitable for the recovery treatment of ground oil produced in the process of oil production operation area, crude oil gathering and transportation, crude oil storage tank cleaning and crude oil leakage.

4. Organic nano-oil sewage separation treatment agent for NGO: It is used for ground waste oil treatment, oil sewage treatment, industrial circulating sewage treatment, etc. In the process of crude oil exploitation.

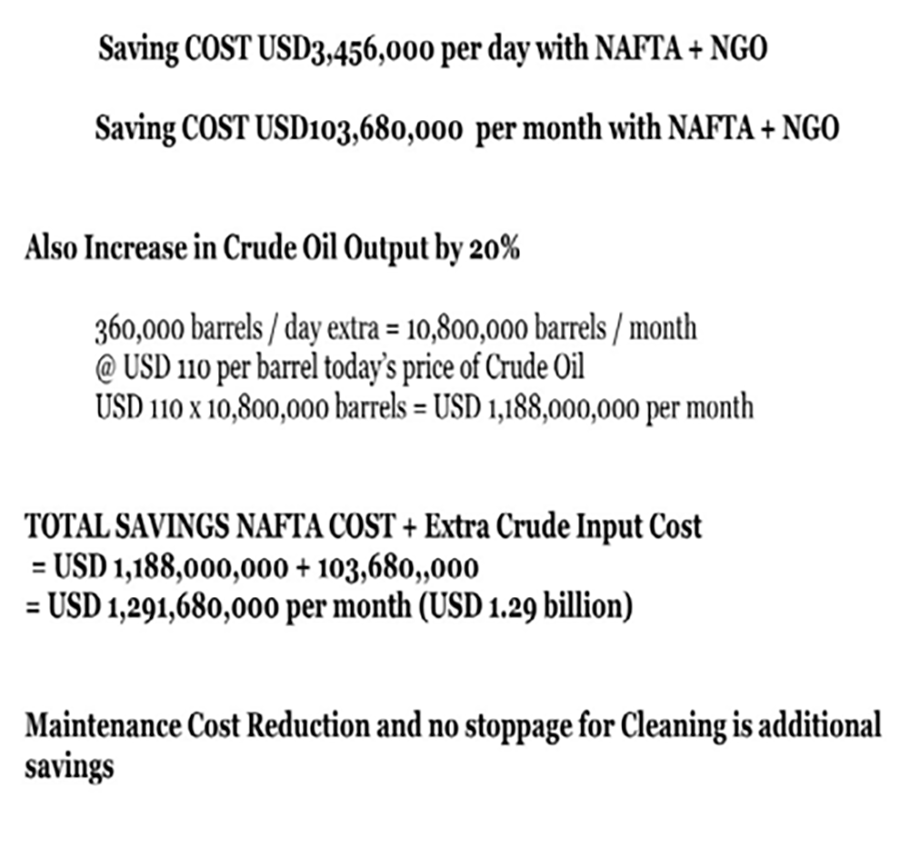

Ⅰ.Active Organic Nanometer Liquid Oil Displacement Agent

The invention relates to a living organic nano-liquid oil displacement agent for NGO, which is a product researched and developed for increasing the oil recovery rate by profile control and oil displacement in an offshore oil and gas field and an onshore oil field. Especially, it is the latest generation of patented products for improving oil recovery, which is developed according to the geological characteristics of low permeability and ultra-low permeability oilfields, the origin of crude oil and the physical properties of crude oil, and is the only green environmental protection product at home and abroad. Its important characteristics are that it is an active organic product of biomass, can be completely biodegradable, is a nano-scale crude oil heavy plasticizer, can quickly penetrate into the molecular chain of crude oil, reshape the molecular chain of crude oil hydrocarbons, and effectively reduce the viscosity of high-viscosity crude oil. The crude oil with high viscosity, such as heavy oil and asphaltene, is effectively and quickly separated from the reservoir layer, and the recovery rate of crude oil can be greatly improved by adopting the organic nano-liquid flooding technology of NGO.

Product technical features:

★ Natural plant matrix and its derivatives are used as basic raw materials

★ Biodegradable nano crude oil heavy plasticizer

★ The product will not cause any toxicity to water, soil and environment.

★ Active organic products

★ It can significantly reduce the viscosity of crude oil and decompose and recombine various hydrocarbon substances.

★ Non-corrosive, non-flammable, non-hazardous, non-toxic chemicals

Active Organic Nanometer Liquid Oil Displacement Agent

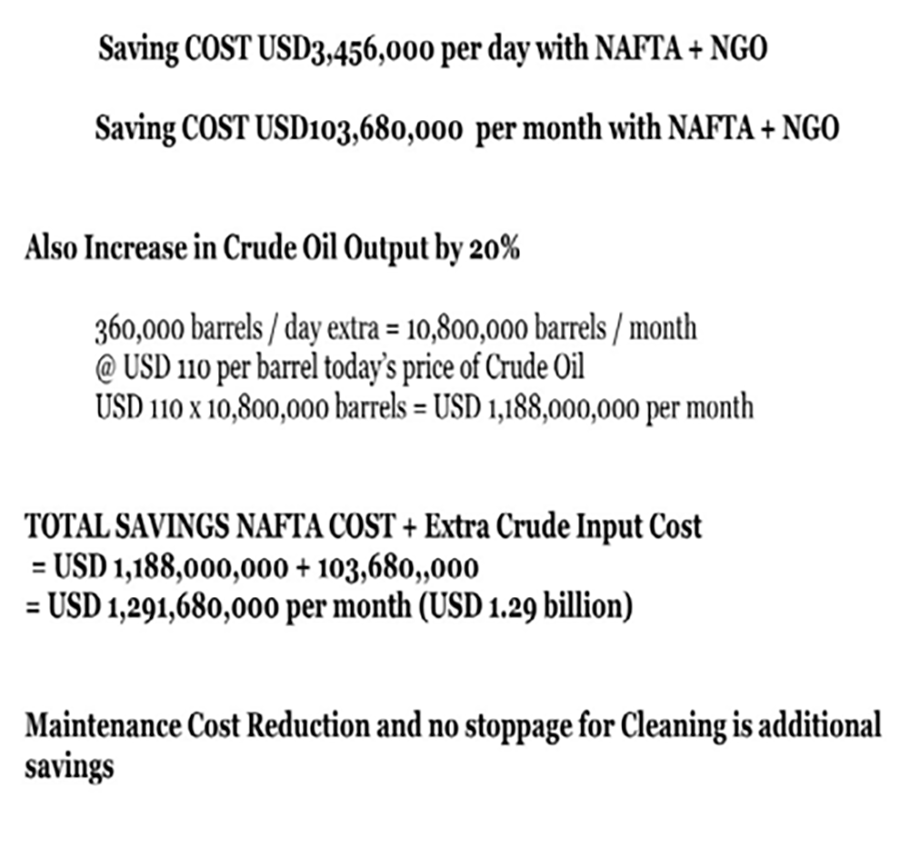

Eor technology has become the most important technology to enhance oil recovery in the world.

Although the use of chemical oil displacement technology can greatly improve oil recovery, however, because chemical oil displacement agents are harmful to the environment and difficult to biodegrade, which brings great damage to the ecological environment, it is an inevitable trend to use green oil displacement technology products from the perspective of environmental protection.

Active organic nano-liquid oil displacement agent is a green innovative product specially developed for improving oil recovery in oil fields. It eliminates any risk of toxicity and does not contain any carcinogenic ingredients. Some international laboratories have approved and confirmed that the product is a clean and safe product, safe for both the environment and human operation.

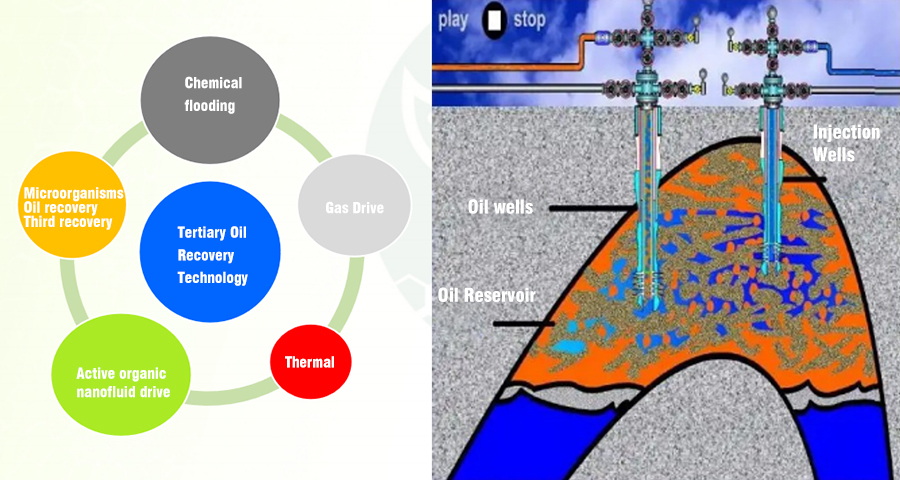

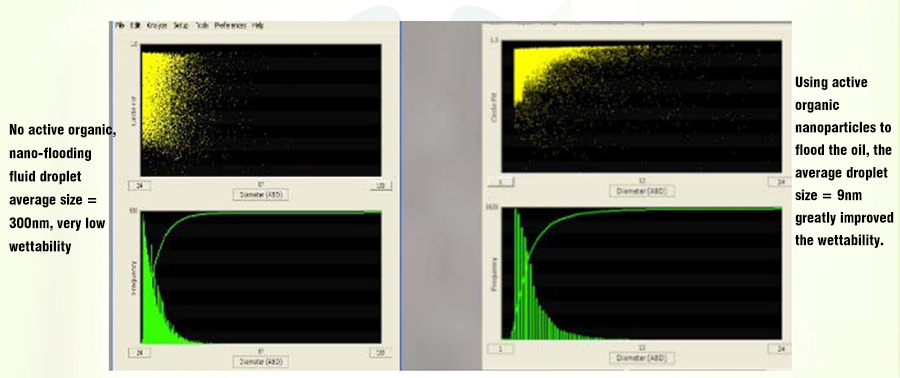

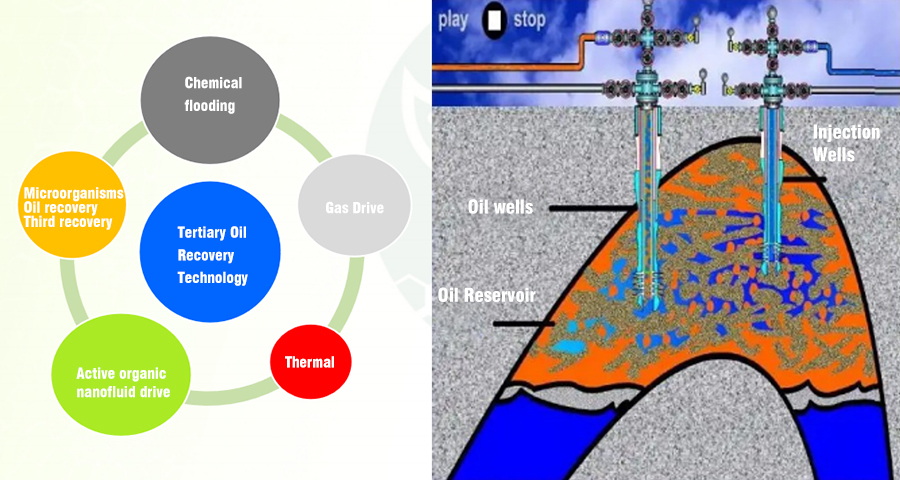

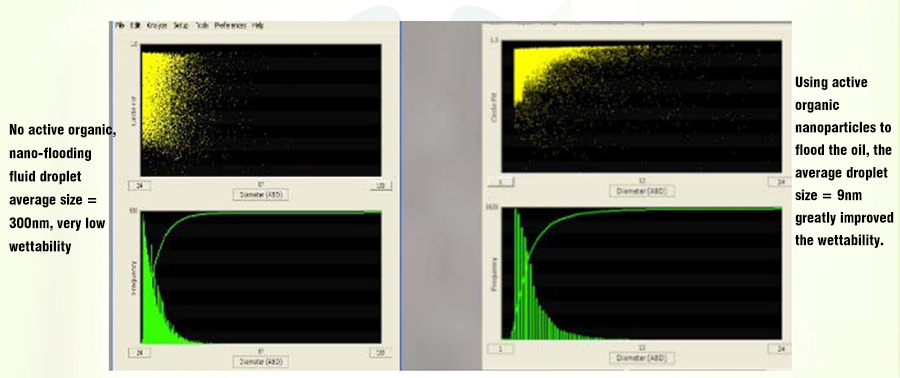

Comparison of the Penetration Effect of Crude Oil and the Effect of Reshaping the Molecular Chain of Crude Oil and the Size Analysis of Droplets between Unused and Used Activated Organic Nanoparticles

Principle of profile control and oil displacement

In the process of oil displacement and enhanced production in the oil field, the organic nano liquid of NGO can quickly penetrate into the molecular chain of crude oil after entering the oil layer, decompose and reshape the compounds such as colloid, asphaltene and the like of the macromolecular chain, and the reshaped crude oil has shorter molecular chain and more homogeneity, thereby greatly reducing the viscosity and the adsorption capacity of the crude oil. Resulting in that the crude oil is easy to separate from the adsorbed rock layer or other geological mineral layers, and meanwhile, the crude oil attached to the petroleum stratum accumulated under the oil production well of the oil field can be quickly stripped out, thereby greatly improving the wettability of the crude oil and playing a great role in the profile control, flooding and extraction of the crude oil.

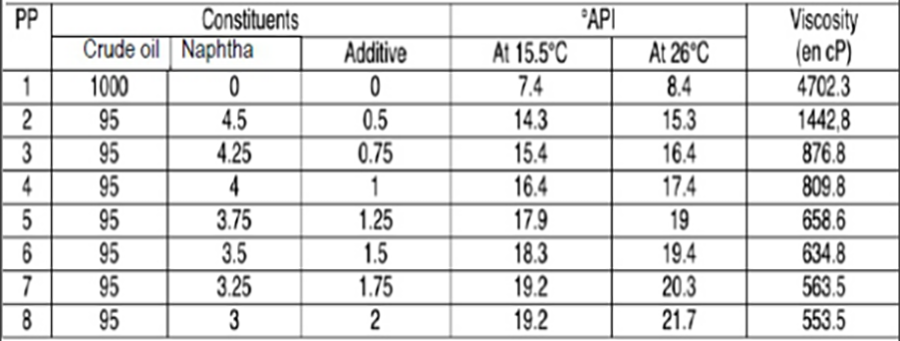

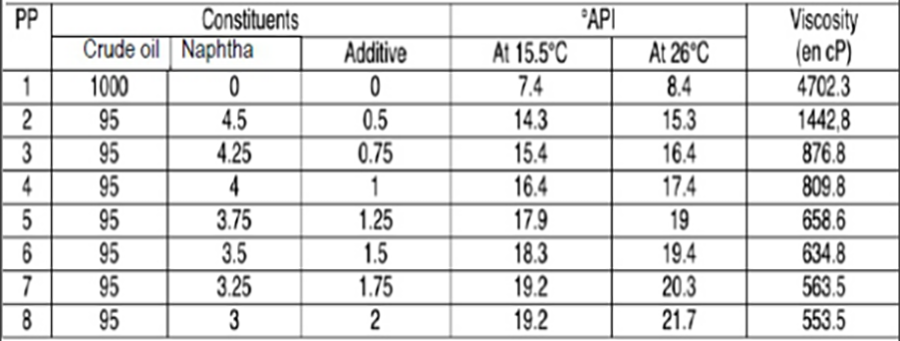

Effect of using active organic nano-oil displacement fluid in heavy oil

Viscosity results obtained for different addition ratios:

That is to say, it reduces the viscosity and has a period of stability, and can significantly increase the API of ultra-heavy crude oil by 200%.

The advantages of the active organic nano-liquid oil displacement agent technology product are as follows:

1. The active organic nano profile control and flooding fluid has a wide range of formation temperature (-35 ℃ ~ 130 ℃), low requirements for groundwater quality, and has the characteristics of chaNGOng the direction of water injection seepage in reservoir pores and expanding the swept volume.

2. The particle size analysis shows that the particle size of the profile control and displacement fluid is nanometer, and the hydration expansion multiple is 100 ~ 150. The core simulation displacement test shows that the injection performance of the nano-fluid is good, and the plugging rate of the single sand pipe is more than 80.5%. In the high and low permeability sand pipe, the nano-fluid preferentially enters and plugs the high permeability pipe, changes the heterogeneity of the double pipe, starts the crude oil in the low permeability pipe, and improves the overall recovery factor by more than 20%.

And 3, that oil-water interfacial tension can be reduce to an ultra-low state of 10-2-10-3mN/m, so that oil drops are easy to deform, the work for discharge the oil drops through pore throats is reduced, the move speed of the crude oil in the stratum is increased, and the oil displacement efficiency is improved.

4. Increase the number of seepage channels. The agent can dredge network pore throats, increase the number of flowable capillaries, activate the retained oil, improve the flowable porosity and permeability of the reservoir, increase the relative permeability of the porous medium to crude oil and water, and increase the seepage velocity.

5. Increase the share of flowable oil. The oil-water interfacial tension is reduced, so that the adhesion force of the crude oil stripped from the rock surface is reduced, the crude oil is separated from the rock, a layer of nano-film can be formed on the crude oil and the rock surface, the oil droplets and the oil film adhered to the rock surface are thoroughly stripped, and the mobile oil share is increased. It provides technical support for enhancing oil recovery in heterogeneous reservoirs.

Features and innovation of product technology:

1. Solve the contradiction between injectivity and plugging ability by using nano-sized materials.

2. It is not sensitive to groundwater salinity and temperature, and is suitable for all kinds of water drive reservoirs.

3. The product acts on the deep part of the reservoir, and the consumption is relatively small, which solves the problem of economic cost.

4. The product has better stability and durability than PAM solution.

5. It can be observed while noting, has a cumulative effect, and solves problems such as process adjustment capability.

6. It can dissolve and disperse rapidly in various oilfield sewage and seawater, and the injection process is very simple.

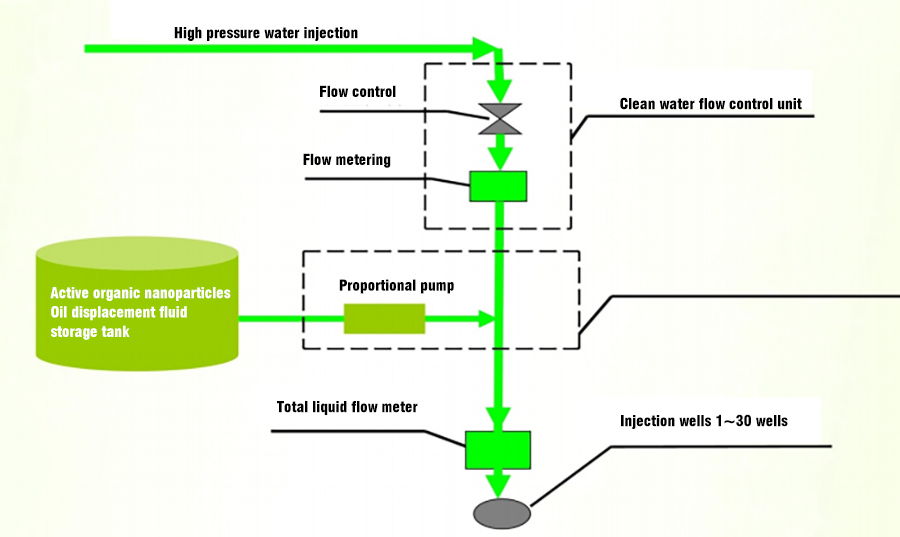

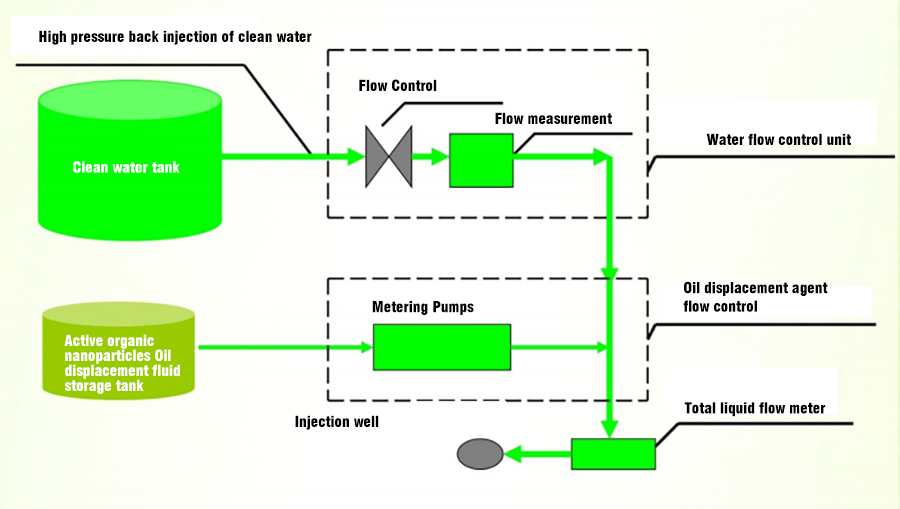

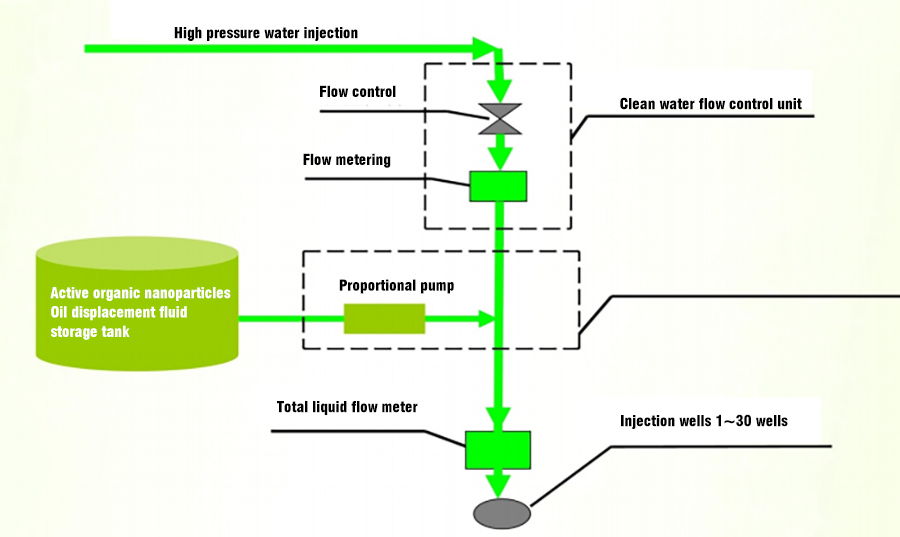

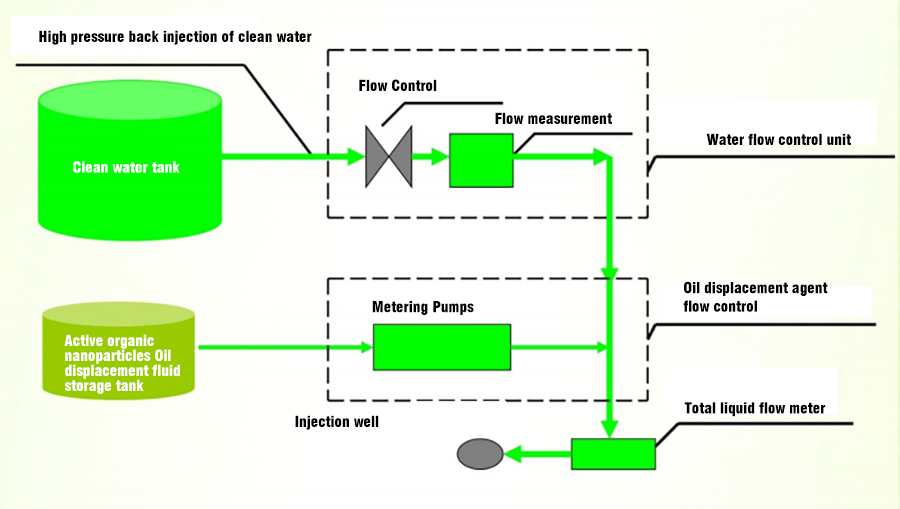

Process Flow Diagram of Centralized Allocation and Injection System for Active Organic Nano-fluid Oil Displacement Agent

Schematic diagram of single-well injection process of active organic nano-fluid oil displacement agent

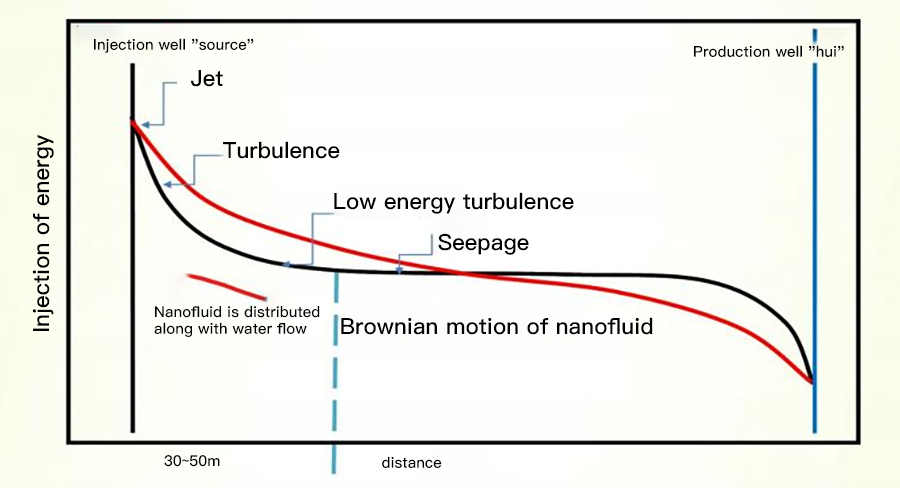

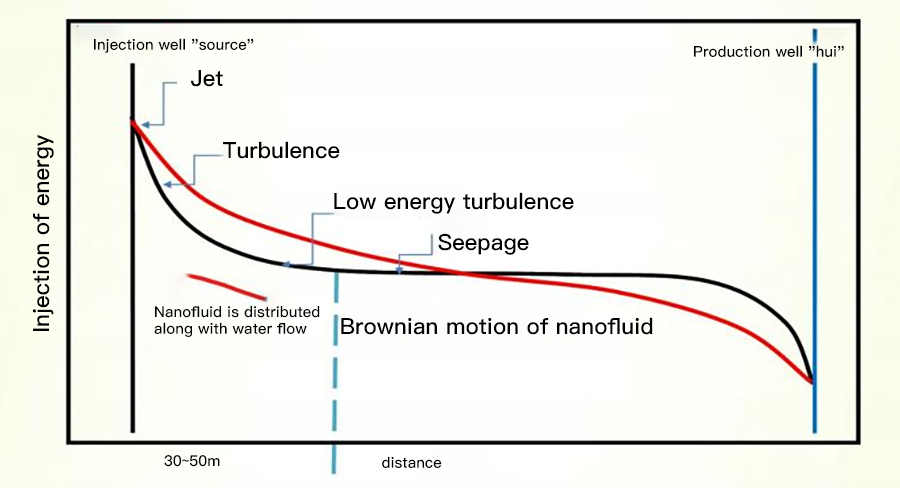

Schematic diagram of distribution of active organic nano-liquid

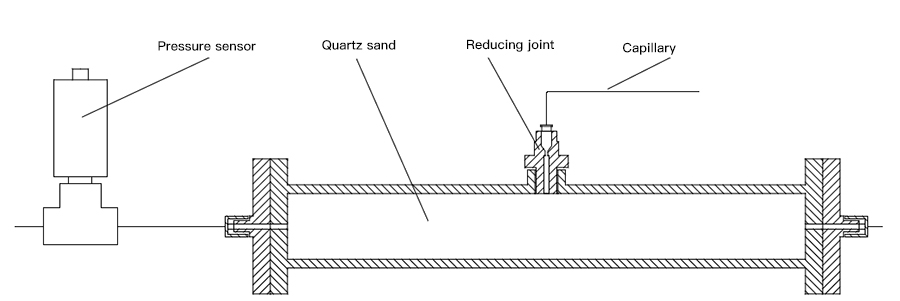

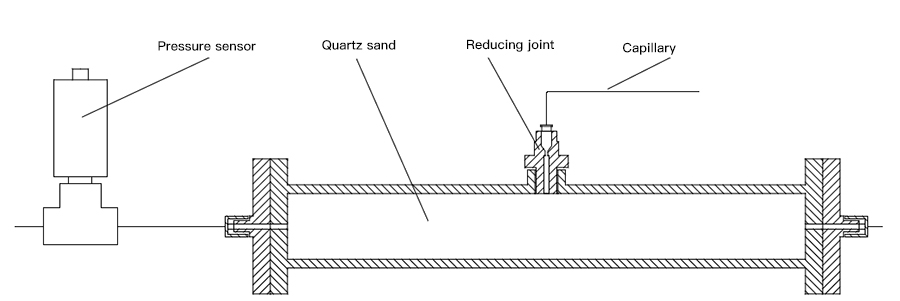

Simulation of formation fracture with glass capillary

Permeability of quartz sand tube: 6.8 mD

Sand filling pipe length: L = 30cm, cross section: A = 11.3354 cm2

Glass capillary length: 20 cm, diameter: 150 μm, 250 μm, 500 μm

Injection rate: 1.67 × 10-3ml/s, 2 × 10-3ml/s, 2.33 × 10-3ml/s, 2.67 × 10-3ml/s, 3 × 10-3ml/s, 3.33 × 10-3ml/s, 3.67 × 10-3ml/s ,4 × 10-3ml/s ,4.33 × 10-3ml/s ,4.67 × 10-3ml/s , 5 × 10-3ml/s

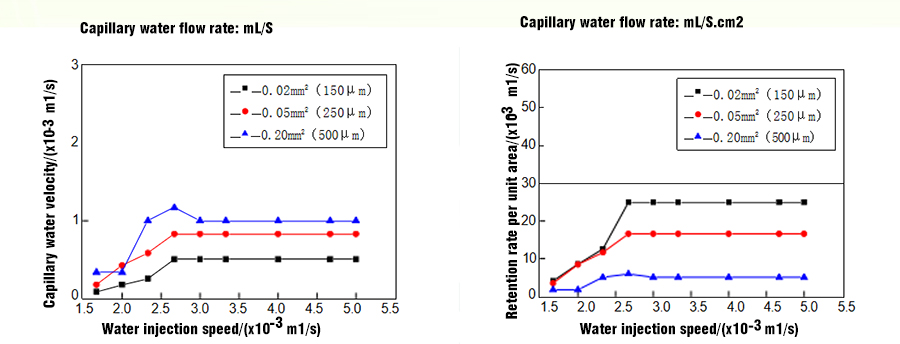

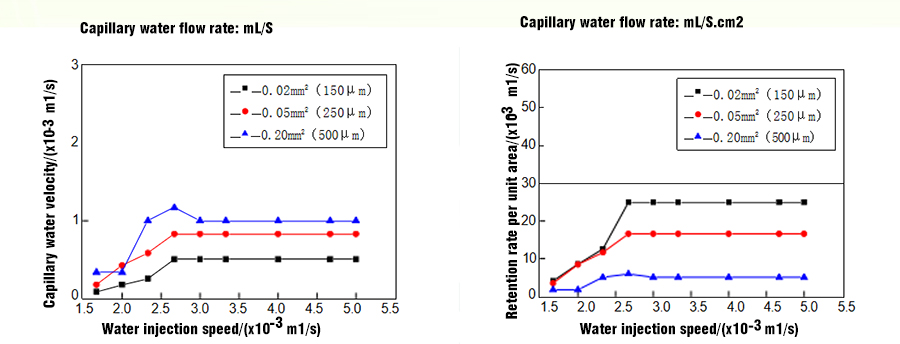

The relationship between the injection flow rate of the sand packing tube and the flow rate of the glass capillary tube and the cross section flow rate

With the increase of the flow rate of the water injected into the sand packing tube, the flow rate of the glass capillary tube increases at first and remains unchanged after reaching a certain value.

The turning point of capillaries with the same diameter is the same. When the sand pack has the same injection flow rate, the flow rate of the capillary increases with the increase of the capillary diameter, but the flow rate (flow rate per unit area of the cross section) decreases. Note: As long as there is enough water in the sand filling pipe where the capillary section is located, the flow rate and flow rate in the capillary depend entirely on the capillary itself.

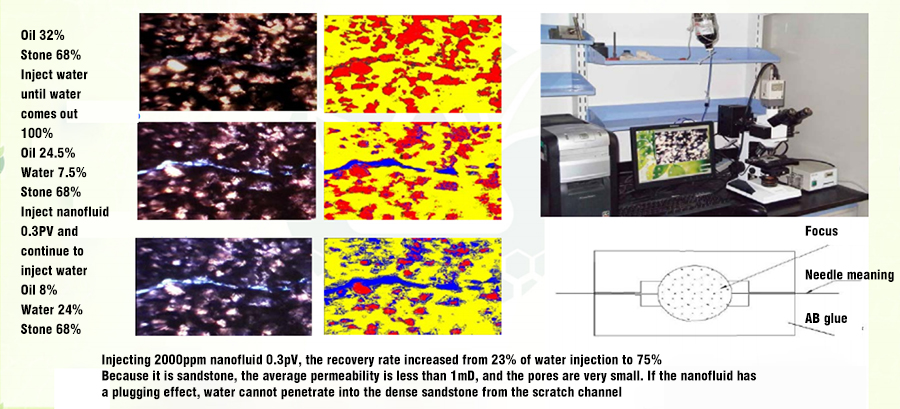

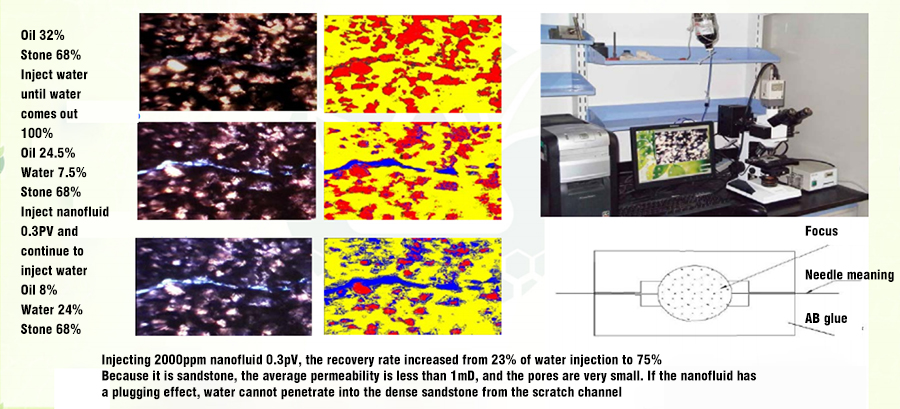

Experiment of enhancing oil recovery by nanosphere technology in tight sandstone fracture model (sandstone, paper knife through scratch)

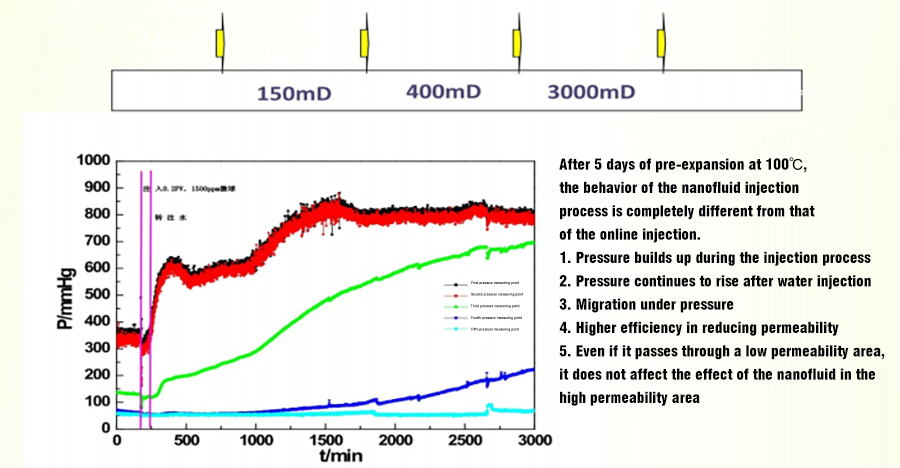

Simulate the migration and work of the expanded nano-fluid in the reservoir

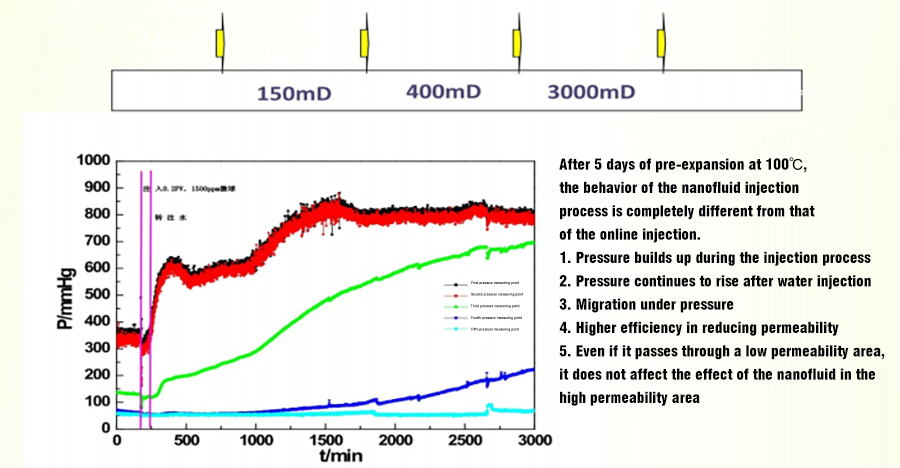

Permeability and its change of sand pipe before and after injecting pre-expanded nano-fluid

| R23 | R34 | R45 |

Initial permeability (mD) | 150 | 400 | 3000 |

Minimum permeability (mD) | 70 | 60 | 180 |

Change in permeability (mD) | 53% | 85% | 94% |

The higher the permeability, the more efficient the nanofluids work!

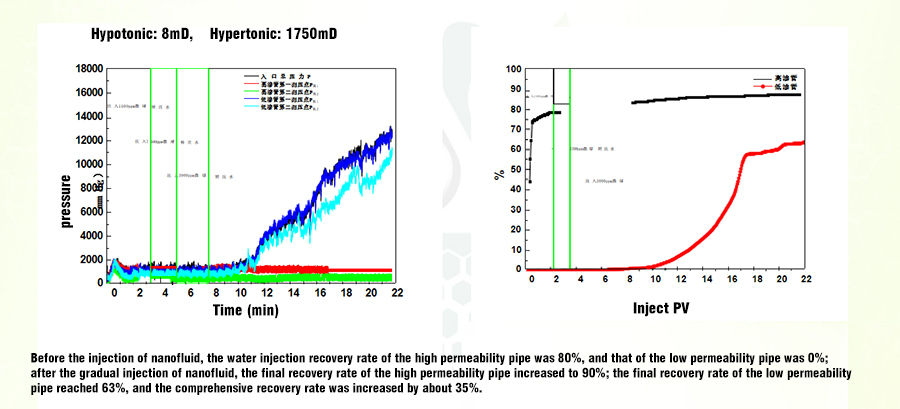

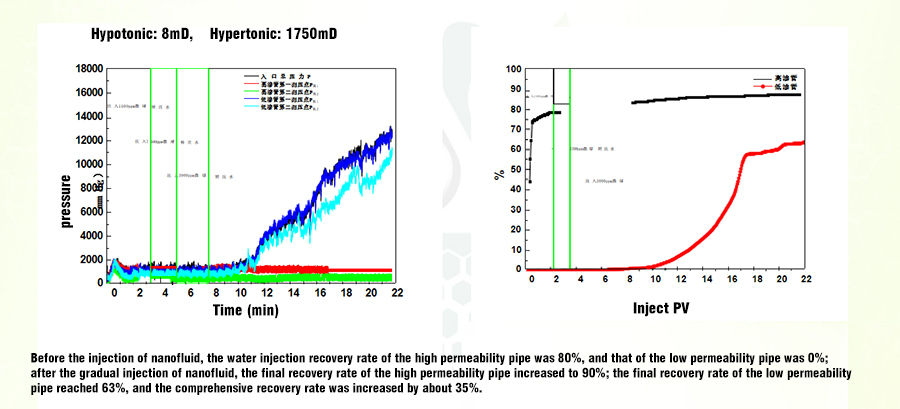

Double tube experiment for enhanced oil recovery

Organic nano-oil displacement fluid for NGO has subversive green environmental protection oil displacement technology innovation.

1. When the permeability difference is less than 20, the crude oil of high permeability and low permeability can be produced by water flooding at the same time, when the permeability difference exceeds 50, the crude oil of low permeability can not be produced by water flooding.

2. The injection of nano-fluid can effectively reduce the permeability of the high permeability part and effectively use the crude oil of the high and low permeability part.

And 3, the injected nano liquid has an energy accumulation effect and can be injected into a plurality of slugs.

4. The larger the permeability difference is, the more nano-liquid is needed.

★ Even if leakage or accidental discharge occurs at the use site, it will not cause any toxicity to water, soil and the environment.

★ The residue of the product in the sea will not produce any toxicity.

Overview of Oilfield Application Products

II. WANWUSHENG NGO — — Active Organic Nano

Viscosity Reducer for Heavy Oil

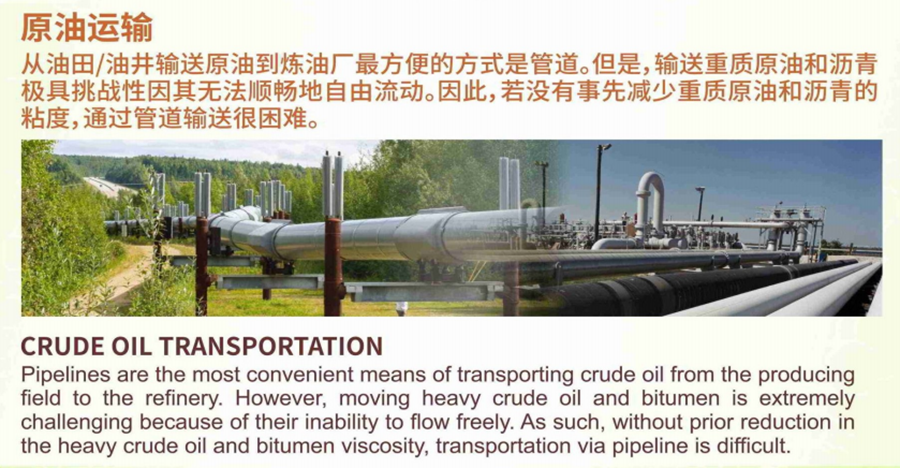

The invention relates to an active organic nano viscosity reducer for heavy oil, which is a product used for reducing the viscosity of heavy oil, improving the recovery ratio and the flow performance of the heavy oil, and helping to solve the problems of heavy oil exploitation, storage and transportation.

It is a kind of green product developed by the research and development team of Universal Life, mainly based on natural plant matrix and its derivatives, screened biosynthetic products such as biosurfactants and enzymes produced by microbial metabolism in oil reservoirs, which have strong dispersio n ability for heavy oil and extra-heavy oil, rapid dispersion of oil-water disturbance and rapid separation of oil-water static. The viscosity of the heavy oil can be reduced under the condition of lower temperature and lower water content due to low concentration used on site, so that the viscosity of the crude oil can be efficiently reduced, the resistance can be wetted and reduced, an adsorption film can be formed on the surface of the pipe wall and the storage tank, and the friction resistance between the oil and the pipe wall can be effectively reduced. It has the ability to reduce the viscosity of heavy oil efficiently, and can withstand extreme reservoir environments such as low temperature and high salinity.

Product technical features:

★ Wide applicable temperature range, resistance to extreme pH and salinity.

★ Wide application range: applicable to thin oil, heavy oil and high pour-point oil reservoirs.

★ Simple construction, lasting effect and low comprehensive cost.

★ The product is low-carbon and environmentally friendly, energy-saving and consumption-reducing, with high input-output ratio and remarkable effect.

★ Safety and environmental protection, biodegradable, no damage to the formation, no environmental pollution, meet the HSE requirements.

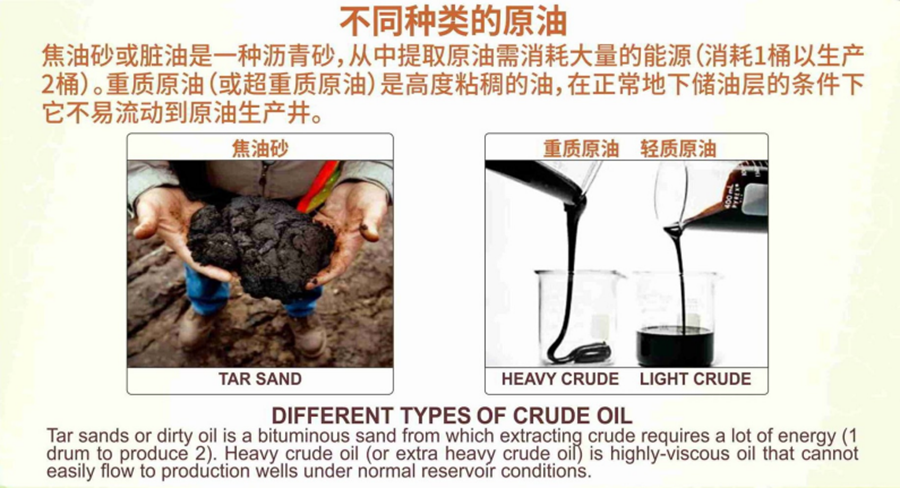

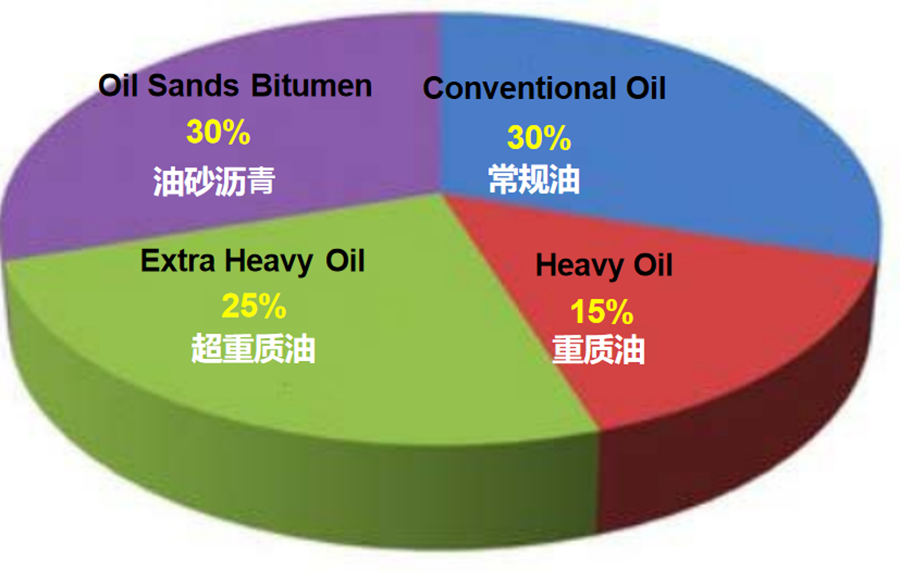

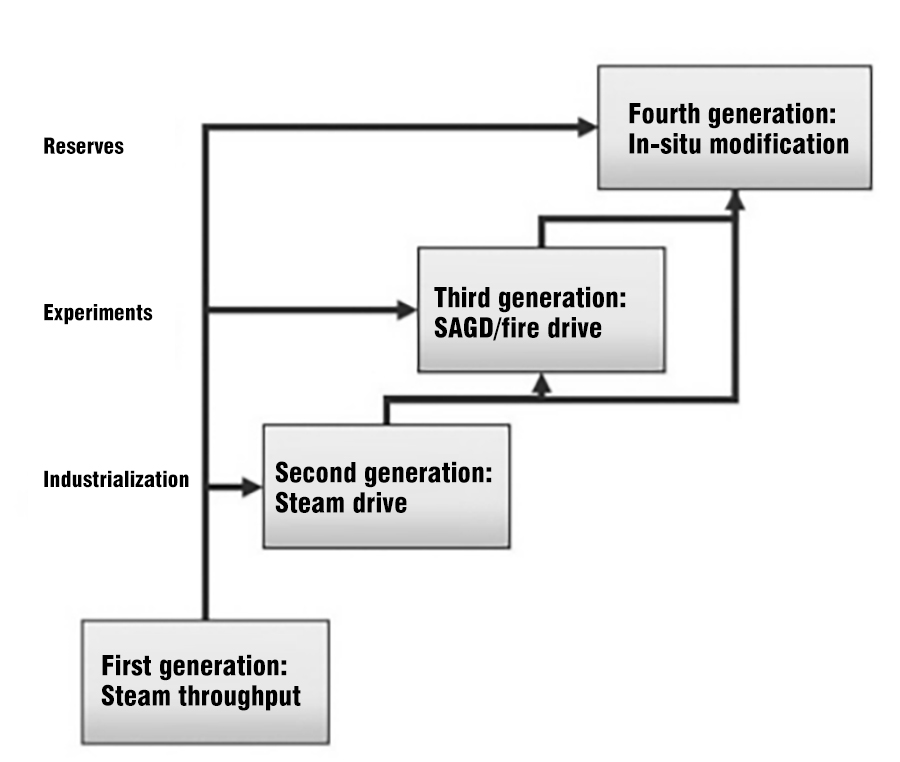

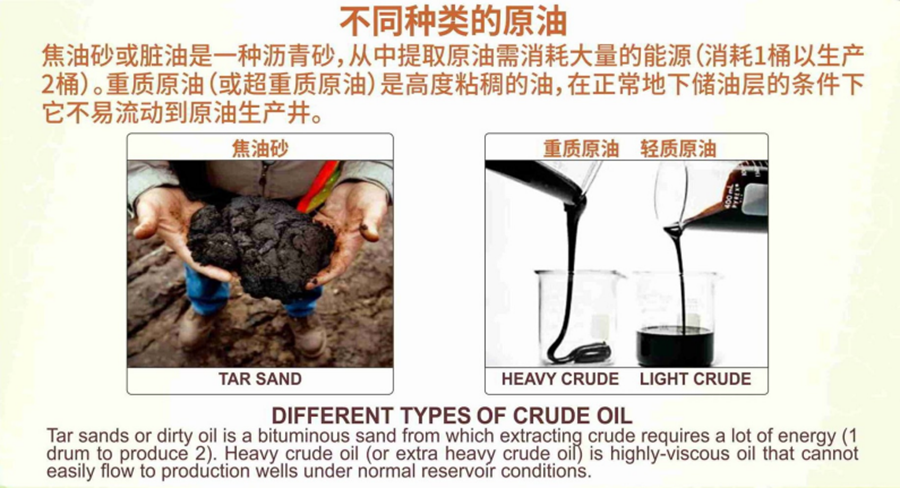

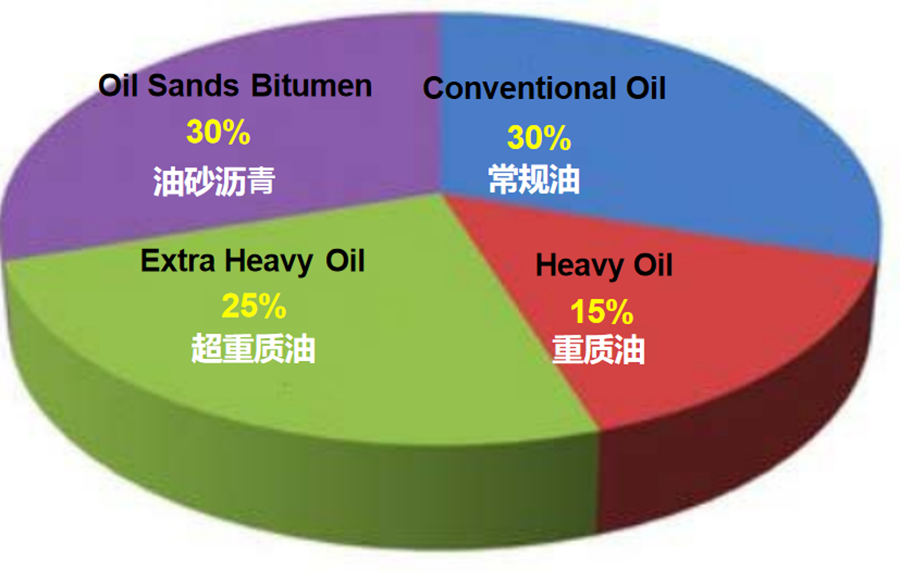

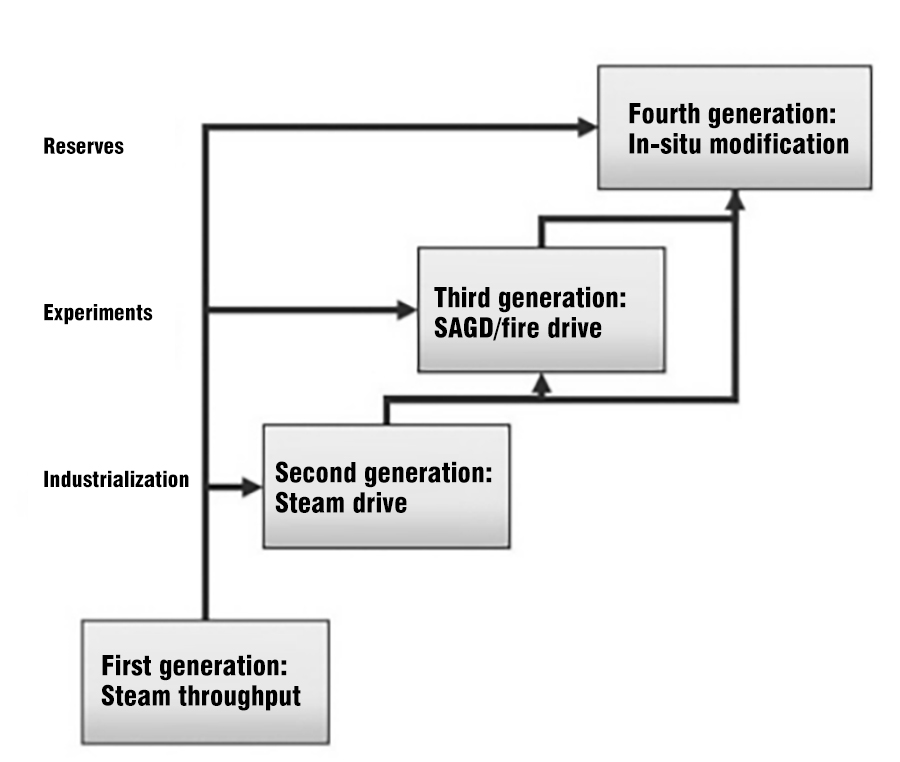

Current status of world oil reserves

The potential of heavy oil resources is huge. 70% of the remaining oil reserves in the world are oil sands and heavy crude oil, resulting in difficulties in the exploitation and transportation of crude oil, energy consumption and many environmental/HSE problems. These crudes usually have a poor API and are very viscous.

China is rich in heavy oil resources, which are estimated to be about 226 × 108 t, and the potential of natural asphalt resources is greater, mainly distributed in the Bohai Bay Basin in the east and the Junggar Basin in the west. Heavy oil has a large amount of resources and a low degree of utilization, and its proportion in future oil production will be significantly increased.

Definition and classification standard of heavy oil

Heavy oil, also known as heavy oil in the world, is a general term for unconventional oil. Different countries have their own usages, for example, Canada calls heavy oil and natural bitumen as oil sand. China customarily calls heavy oil as heavy oil, which is divided into ordinary heavy oil, extra heavy oil and super heavy oil according to its viscosity, petroleum geology calls it heavy oil, natural bitumen as tar sand or oil sand, and heavy oil and oil sand are studied separately.

Classification of heavy oil | Main index (viscosity/mPa · s) Auxiliary index (relative density) |

Name Level |

Ordinary heavy oil | Ⅰ-1

Ⅰ-2 | 50~100

100~10000 | >0.920 |

Extra heavy oil | Ⅱ | 10000~50000 | >0.950 |

Super heavy oil (natural asphalt) | Ⅲ | >50000 | >0.980 |

Product technology application of Wanwusheng NGO for thick oil exploitation

The existing heavy oil is fully exploited by adopting a thermal recovery process technology, the active organic nano heavy oil viscosity reducer of the universal living NGO has the most advanced in-situ modification technology at present, and the existing heavy oil well is injected with the active organic nano heavy oil viscosity reducer of the universal living NGO according to the geological conditions of different oil wells under the condition of not adopting steam flooding thermal recovery, The viscosity and the stripping degree of the crude oil in the reservoir can be modified in situ, the recovery efficiency of the crude oil is improved to the maximum extent, and the oil yield of the heavy oil well is improved.

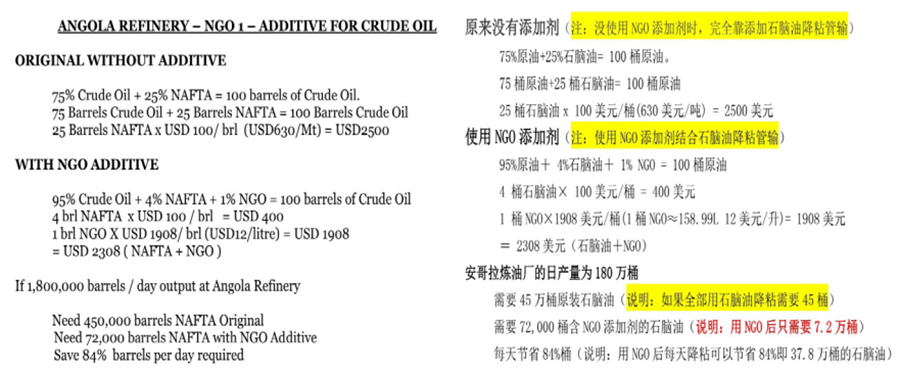

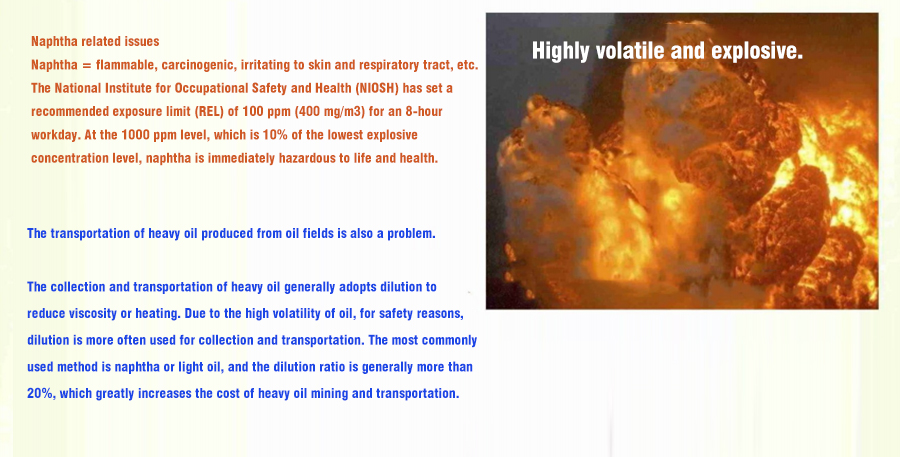

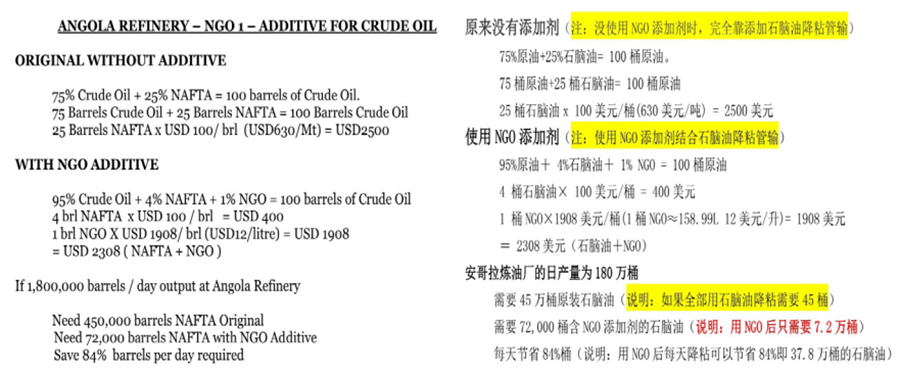

Application of Viscosity Reducer for Wanwusheng Heavy Crude Oil in Angola Refinery

Note: This is the accounting table for reducing the cost by using NGO additives to reduce the use of naphtha when the crude oil of Angola Refinery is transported by naphtha pipeline. The unit of measurement for accounting barrels is the international unit of measurement, and one barrel is about 158.99 liters.