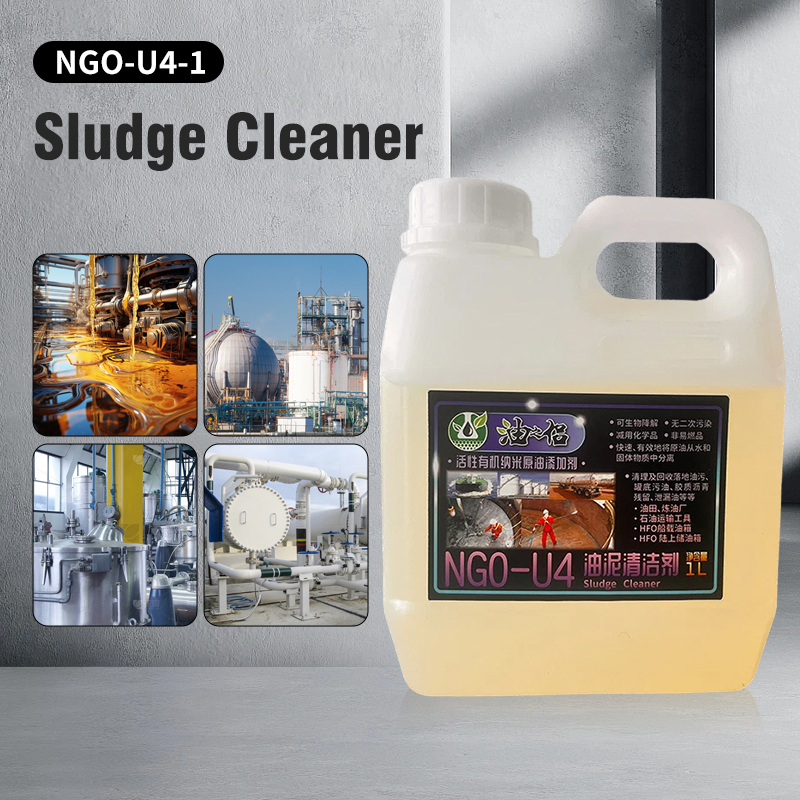

NGO-U4-1 Sludge Cleaner

NGO-U4-1

Clean up and repair the environment polluted by leaked crude oil, reduce the use of chemicals for cleaning up and recovering crude oil/fuel oil, can be applied to COTBS (crude oil tank sludge), crude oil sludge, refinery sludge, commercial ship fuel tanks, etc., Rapid separation &, layering, non-flammable, biodegradable, green, energy-saving and environmentally friendly product.

NGO-U4-1 can clean the hardest crude oil colloid, asphalt and other insoluble substancesThe crude oil component contains a large amount of asphaltene and colloid. Due to the external environment and its own composition and structure characteristics, asphaltene and colloid precipitation and adsorption often occur in the actual process of mining, transportation, storage and processing. With its unique characteristics, colloidal asphaltene can deposit on the surface of the contact medium to form surface deposition, which has a great negative impact on the actual application. Therefore, the prevention and treatment of colloid and asphaltene hazards is an important work.

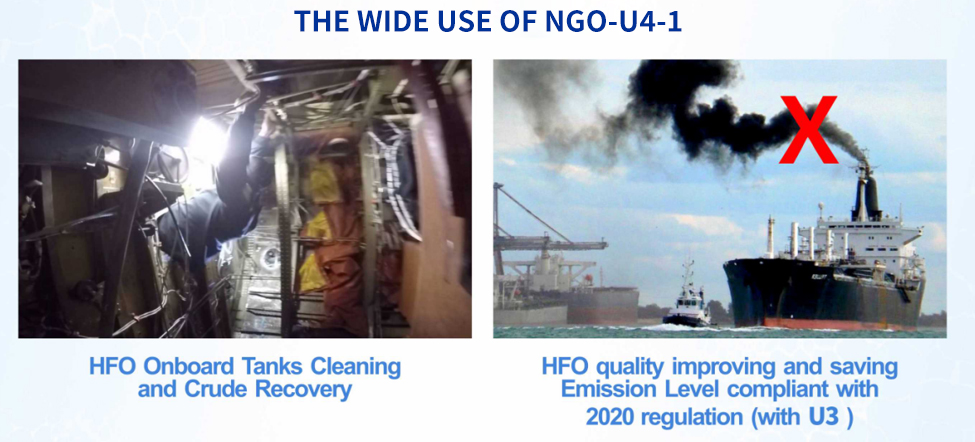

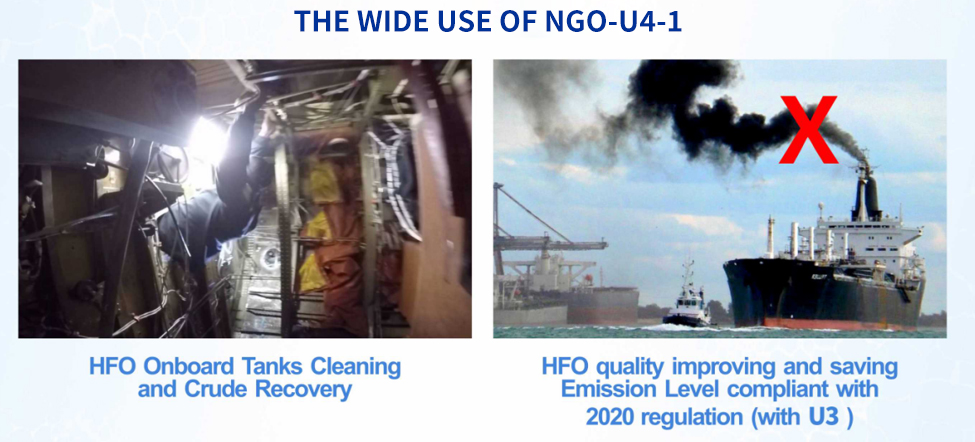

Hazards of asphaltene and colloid in crude oil during storage and transportation: the content and properties of asphaltene and colloid in crude oil affect the viscosity of crude oil. The more asphaltene and colloid in crude oil, the higher the viscosity of crude oil. To effectively reduce the viscosity of crude oil,the traditional methods used still have some shortcomings. In the past, heating method was used to increase the original temperature of crude oil, but this method would cause asphaltene to precipitate on the surface of the heater and eventually form carbon deposition, affecting the heat transfer efficiency.Hazards of asphaltene and colloid in the process of petroleum refining: In the process of crude oil refining, heavy oil contains a large amount of asphaltene and colloid, so the blockage problem caused by asphaltene and colloid in the refining pipeline and equipment will often occur. At the same time, because the asphaltene is rich in high acid functional groups, it will also cause certain corrosion to carbon steel equipment and pipeline. In addition, The asphaltene of crude oil contains a large amount of heavy metal elements, which will cause catalyst poisoning. Asphaltene also contains a large amount of polycyclic aromatic hydrocarbons. When a certain temperature is reached, the accumulation and condensation of asphaltenes will cause carbon deposits in the equipment,thereby blocking the pipeline.Petrol Mates NGO-U4-1 can rapidly and effectively decompose the asphaltene, colloid and other insoluble substances in crude oil. The new biotech process developed by Petrol Mates NGO-U4-1 can manage the cleaning and recycling of crude oil waste, crude oil storage & transportation, processing facilities and heavy oil tanks with better cost efficiency.NGO-U4-1- Disruptive Innovation In Heavy Oil Decomposition & Cleaning TechnologyTaking ship heavy fuel as an exampleIn 2020, the total number of commercial ships of 100 gross tons and above in the world will be 98000, totaling 2.06 billion tons. By January2021, the transport capacity will be equivalent to 2.13 billion dwt. The data shows that the current global consumption of marine fuel oil is about 300 million tons.Given that most ships still using high-viscosity high-sulfur fuel oil (HSFO), which will adhere to the inner wall of the oil tank, forming a layer of semi-solid material containing sediment and asphaltic sludge, and also deposit in the fuel oil pipeline, sedimentation tank and daily tank, which does not meet the requirements of environmental protection and emissions, but also increases the operating cost. Therefore it is necessary to regularly clean the ship's fuel tank and the ship's fuel system pipeline. The time required for a ship to enter the dock for fuel tank cleaning varies from ship to ship, but generally speaking, the average time required for each fuel tank cleaning is 2-4 days, plus the flushing of the ship' s fuel system pipeline, the time required for each ship to thoroughly complete the cleaning and flushing is about 1-2 weeks. In addition to manual cleaning, ships can also use special additives to gradually clean the sediment and asphaltene sludge in HSFO oil tanks and fuel systems. This method is relatively safe and simple, which can save a lot of time and economic costs for the ships.The application of NGO-U4-1 product technology can significantly improve the reaction rate and separation rate of crude oil to be treated. In other words~shorten the crude oil cleaning recovery time and increase the crude oil recovery rate.NGO-U4-1 is tailor-made for the purpose of decomposing long hydrocarbon bonds. It selectively decomposes and reconstructs this molecular chain, effectively reducing the viscosity of petroleum and effectively decomposing, stripping and layering high viscosity colloid and asphaltic oil sludge.

Product Application Prospect Of NGO-U4-1Undoubtedly, China's growing oil demand will have a major impact on climate change, air quality and people's quality of life. The carbon footprint left by oil is obvious. With the increase of oil consumption, the expansion of overseas oil investment and the improvement of capacity, China will play a key role in the Asian and even global oil product market.

Product Application Prospect Of NGO-U4-1Undoubtedly, China's growing oil demand will have a major impact on climate change, air quality and people's quality of life. The carbon footprint left by oil is obvious. With the increase of oil consumption, the expansion of overseas oil investment and the improvement of capacity, China will play a key role in the Asian and even global oil product market.

Even if economic growth slows down, China's oil consumption will still maintain an annual growth rate of about 5%. To meet this demand, China will have to use "dirty oils" that are cheaper but more environmentally damaging, such as oil from the tar sands. Without new regulations that take environmental changes or carbon taxes into account, China's growing demand for oil will have a significant negative impact on air quality and climate change.

Another major environmental challenge facing China is water, an indispensable resource when extracting heavy oil through fracking. Therefore, the development of unconventional oil will have to compete with agricultural, industrial and urban users for limited water resources. In addition, the sewage treatment during the fracking process is another difficult problem for China.

There are more than 3000 kinds of auxiliaries and additives used in petroleum from oil field exploitation to gathering & transporting, refining, and deep processing of refined oil products, fuel oil and fine chemical products. Many of those additives are toxic, harmful, environmentally polluting, and non-degradable products, which will leave a large amount of hazardous waste after use. To reduce the environmental impact of petroleum resource development, the best way is to promote the use of environmentally friendly, degradable and non-polluting petroleum additives, the country is also promulgating various promotion policies. At present, the active nano-biological petroleum additives produced by Petrol Mates NGO-U4-1 can be applied in the entire industrial chain of petroleum processing, and are environmentally friendly and non-polluting, biodegradable, and will not cause secondary pollution in the process of use. The market development and application prospects in the future are huge.

●NGO-U4-1 complies with HSE standards.

●NGO-U4-1 is an active bio-organic environmental friendly and degradable green product, made mainly from natural plant and its derivatives. It can effectively separate the crude oil from water and solid matters. It is a biodegradable nano re-formulator. Its very high flash point prevents any thermal degradation, even if mixed in hot pressurized water.

●lf used in in-situ mining, in the event of leakage or discharge into ground water, NGO-U4-1 will not have any toxic impact on the water, to the soil and to the environment.

●Remnants of NGO-U4-1 in the sea will not have any toxic impact.

●lt is suitable for the cleaning of oil transportation tanks, the bottom of oil storage tanks, the bottom of heavy oil and residual oil tanks, the sump oil pool, the cleaning of colloidal asphalt residues and oil recovery.

●lt is suitable for the cleaning of oil pollution and oil recovery in oil fields and refineries.

●lt is suitable for cleaning and oil recovery of ship-borne oil tanks, heavy oil tanks of ocean-going ship sand oil spills from ships.